2024 Engineering Design Expo

Design, build, impact

The 2024 Engineering Design Expo showcased the achievements and innovation of students across the Allen School of Engineering and Computing's seven academic departments and 12 degree programs. We are grateful for the support of our industry sponsors that account for the majority of our total projects. Take a look at how Trine students are engineering the future.

Jim and Joan Bock Department of Biomedical Engineering

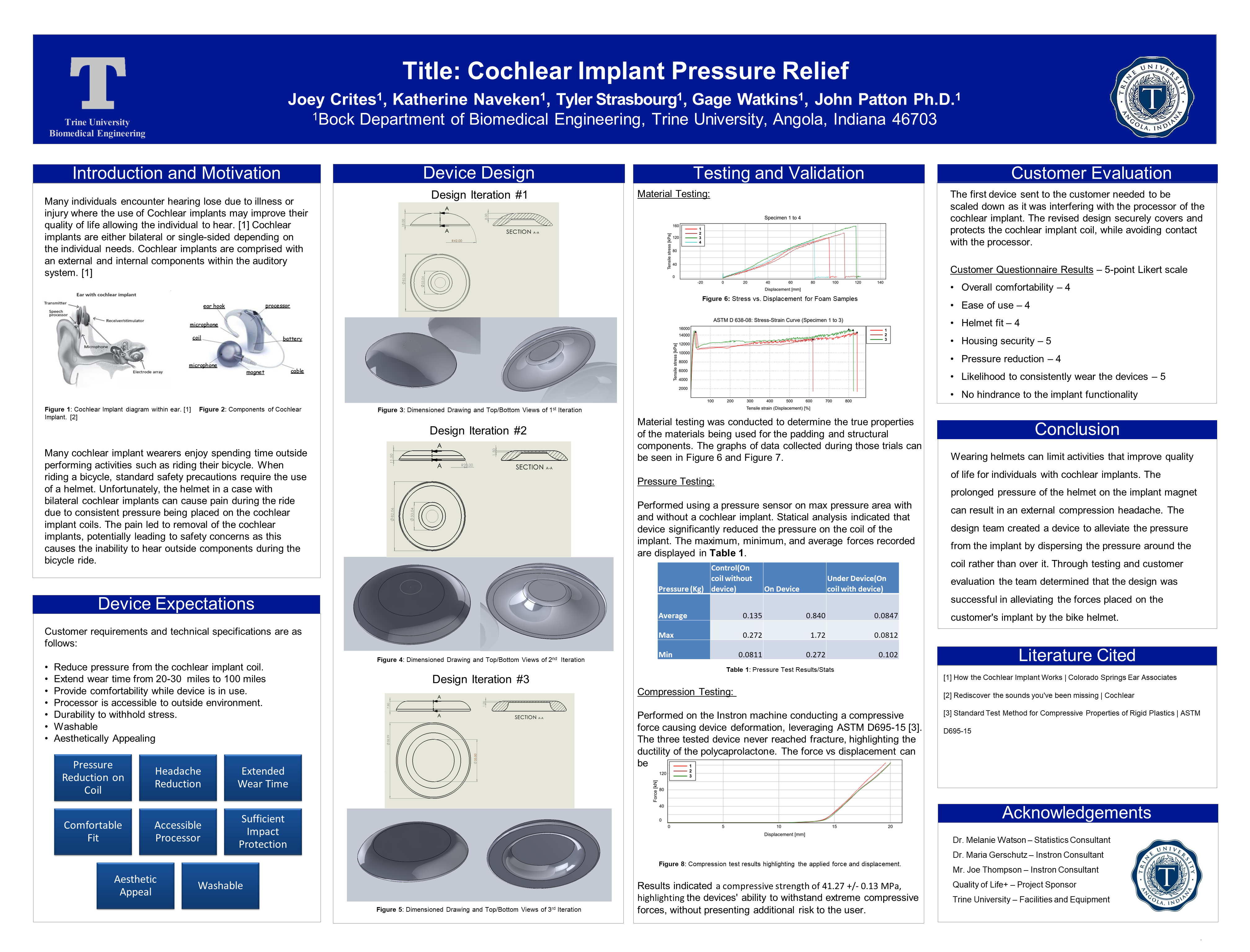

Many cochlear implant wearers enjoy spending time outside performing activities such as riding their bicycle. When riding a bicycle, standard safety precautions require the use of a helmet. Unfortunately, the helmet in a case with bilateral cochlear implants can cause pain during the ride due to consistent pressure being placed on the cochlear implant coils. The pain led to removal of the cochlear implants, potentially leading to safety concerns as this causes the inability to hear outside components during the bicycle ride.

Members: Joey Crites, Katherine Naveken, Tyler Strasbourg and Gage Watkins

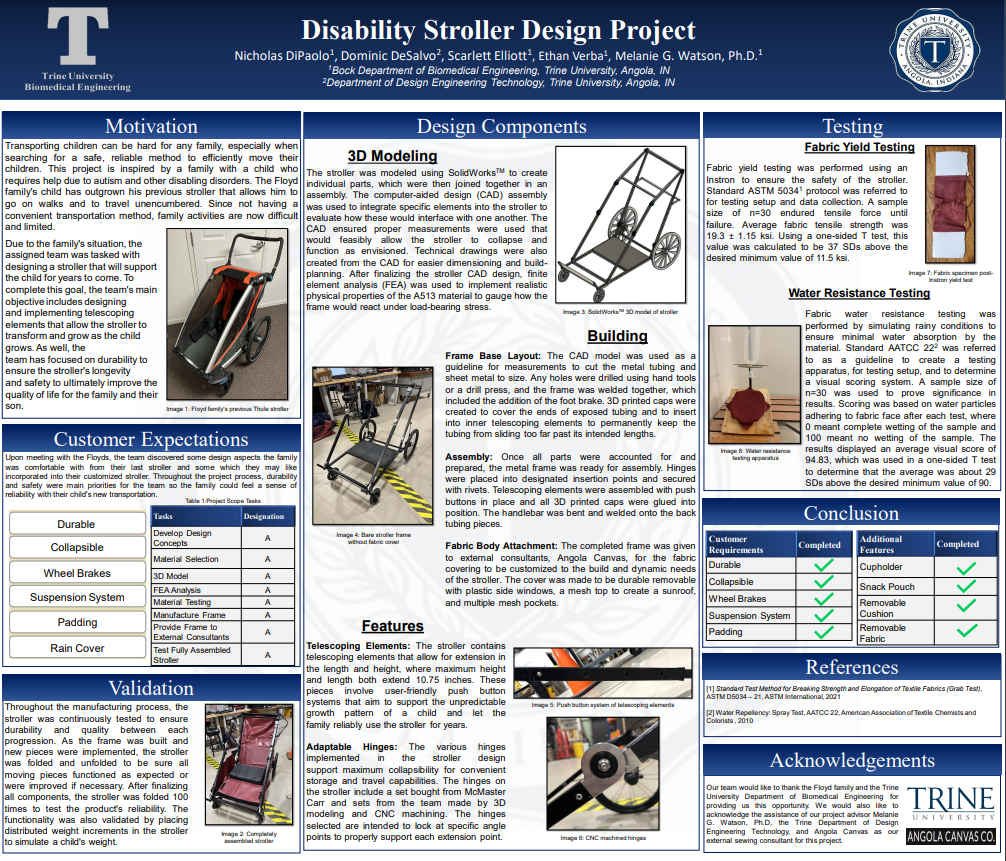

Transporting children can be hard for any family, especially when searching for a safe, reliable method to efficiently move their children. This project is inspired by a family with a child who requires help due to autism and other disabling disorders. The Floyd family's child has outgrown his previous stroller that allows him to go on walks and to travel unencumbered. Since not having a convenient transportation method, family activities are now difficult and limited.

Members: Nicholas DiPaolo, Dominic DeSalvo, Scarlett Elliott and Ethan Verba

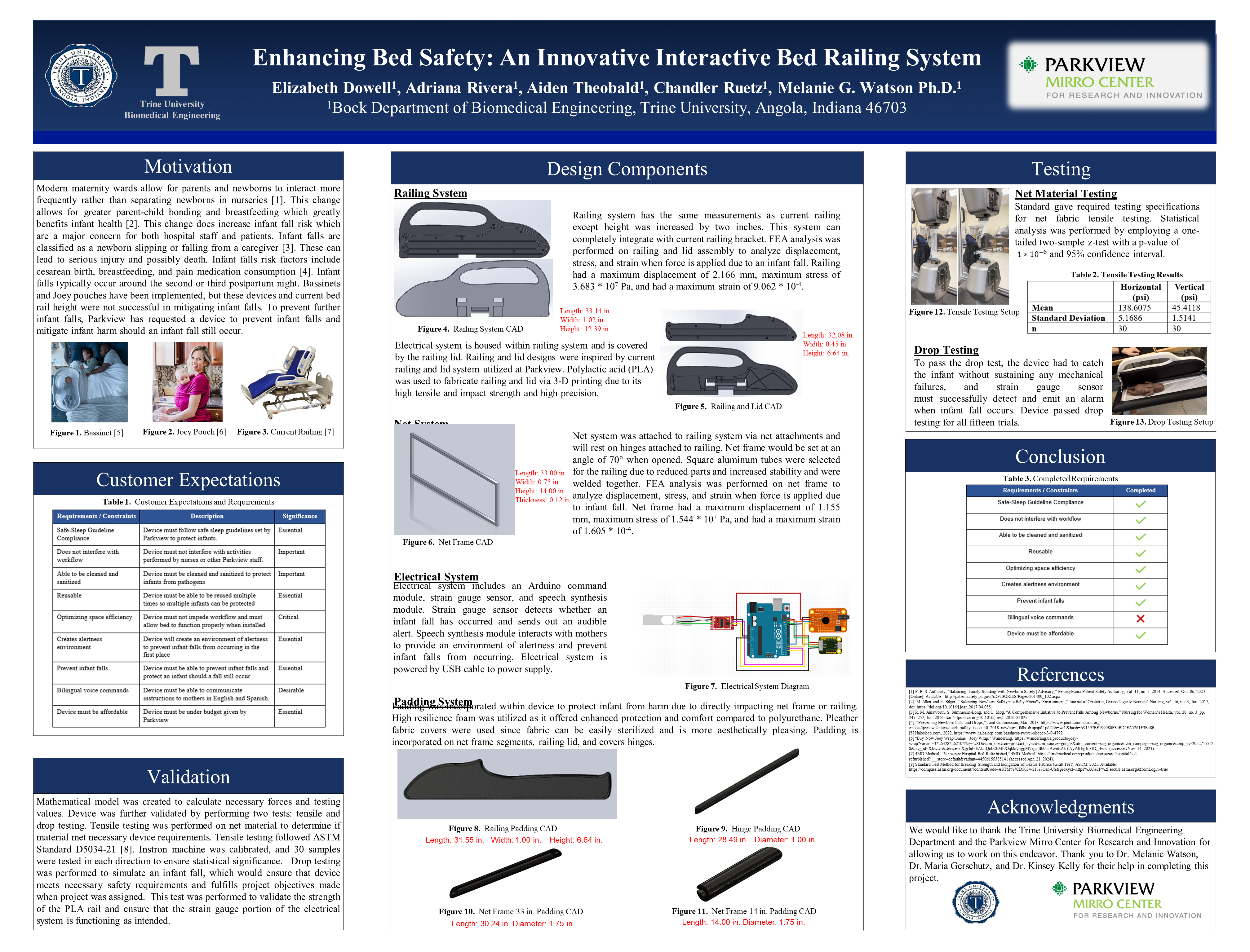

Modern maternity wards allow for parents and newborns to interact more frequently

rather than separating newborns in nurseries. This change allows for greater parent-child

bonding and breastfeeding which greatly benefits infant health. This change does increase

infant fall risk which are a major concern for both hospital staff and patients. Infant

falls are classified as a newborn slipping or falling from a caregiver. These can

lead to serious injury and possibly death. Infant falls risk factors include cesarean

birth, breastfeeding, and pain medication consumption. Infant falls typically occur

around the second or third postpartum night. Bassinets

and Joey pouches have been implemented, but these devices and current bed rail height

were not successful in mitigating infant falls. To prevent further infant falls, Parkview

has requested a device to prevent infant falls and mitigate infant harm should an

infant fall still occur.

Members: Elizabeth Dowell, Adriana Rivera, Aiden Theobald and Chandler Ruetz

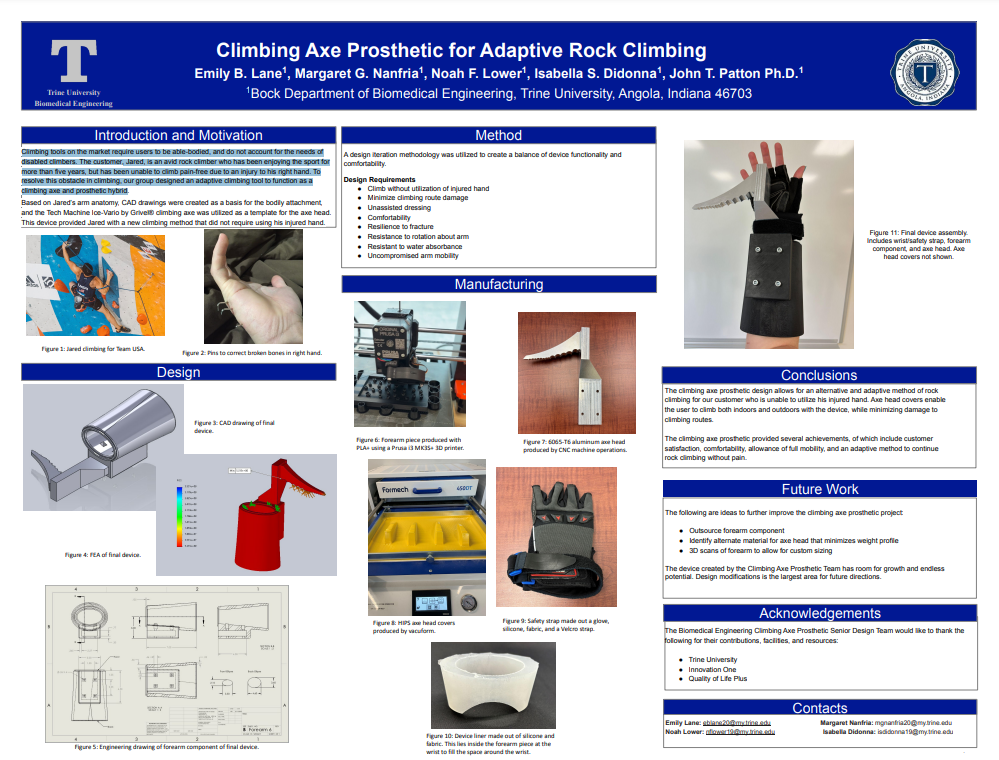

Climbing tools on the market require users to be able-bodied, and do not account for

the needs of

disabled climbers. The customer, Jared, is an avid rock climber who has been enjoying

the sport for

more than five years, but has been unable to climb pain-free due to an injury to his

right hand. To resolve this obstacle in climbing, our group designed an adaptive climbing

tool to function as

a climbing axe and prosthetic hybrid.

Members: Emily B. Lane, Margaret G. Nanfria, Noah F. Lower and Isabella S. Didonna

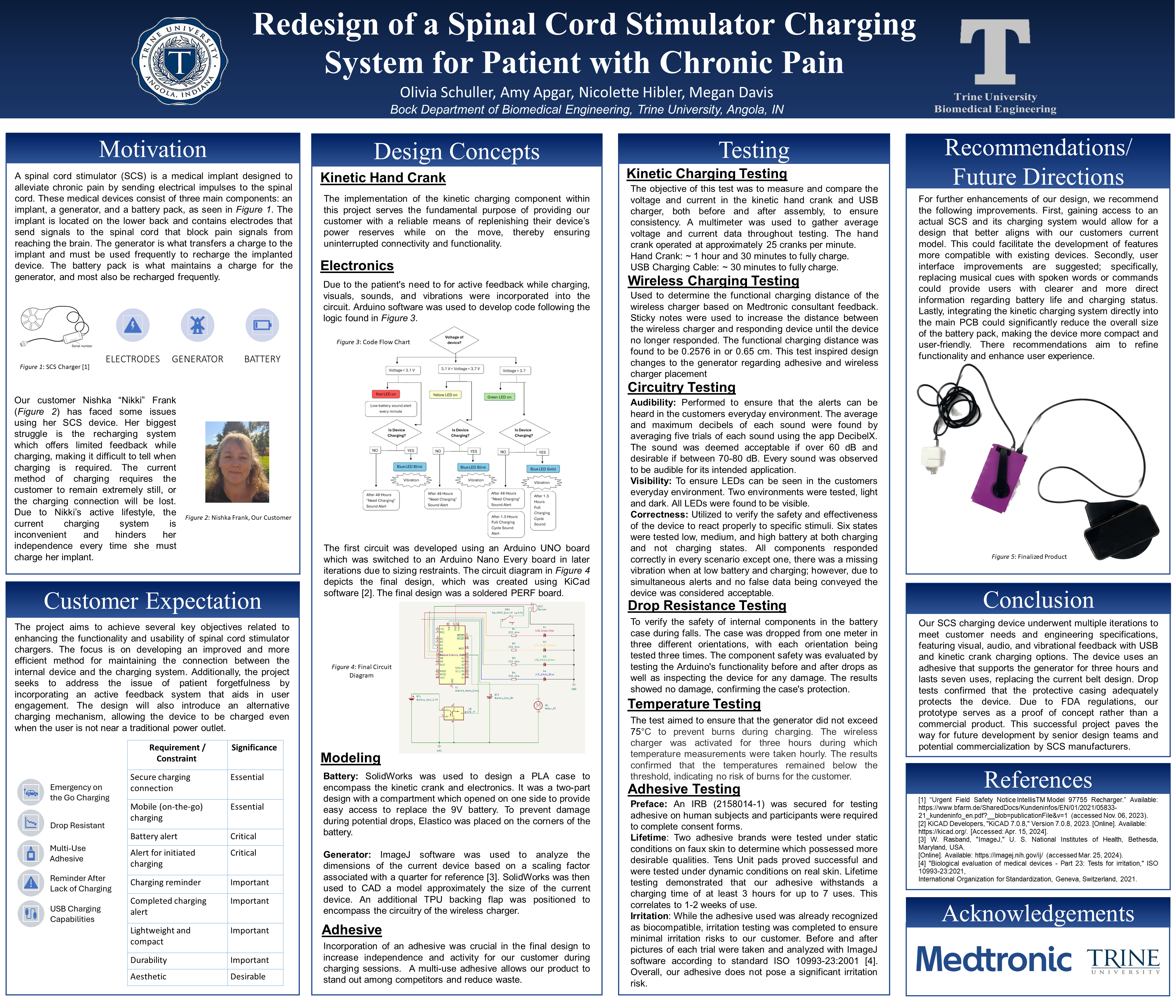

A spinal cord stimulator (SCS) is a medical implant designed to alleviate chronic pain by sending electrical impulses to the spinal cord. These medical devices consist of three main components: an implant, a generator, and a battery pack, as seen in Figure 1. The implant is located on the lower back and contains electrodes that send signals to the spinal cord that block pain signals from reaching the brain. The generator is what transfers a charge to the implant and must be used frequently to recharge the implanted device. The battery pack is what maintains a charge for the generator, and most also be recharged frequently.

Members: Olivia Schuller, Amy Apgar, Nicolette Hibler and Megan Davis

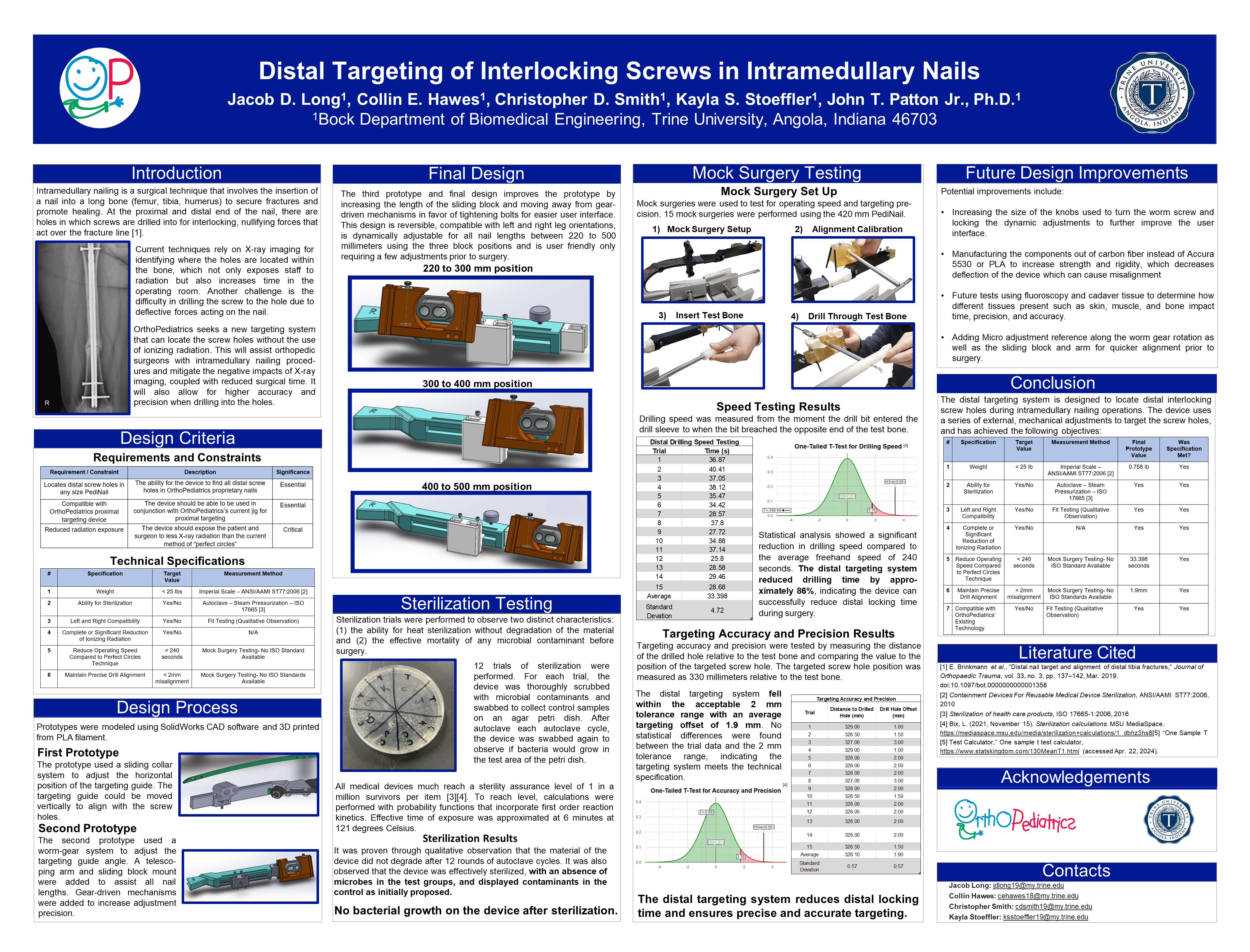

Intramedullary nailing is a surgical technique that involves the insertion of a nail into a long bone (femur, tibia, humerus) to secure fractures and promote healing. At the proximal and distal end of the nail, there are holes in which screws are drilled into for interlocking, nullifying forces that act over the fracture line. Current techniques rely on X-ray imaging for identifying where the holes are located within the bone, which not only exposes staff to radiation but also increases time in the operating room. Another challenge is the difficulty in drilling the screw to the hole due to deflective forces acting on the nail.

Members: Jacob D. Long, Collin E. Hawes, Christopher D. Smith and Kayla S. Stoeffler

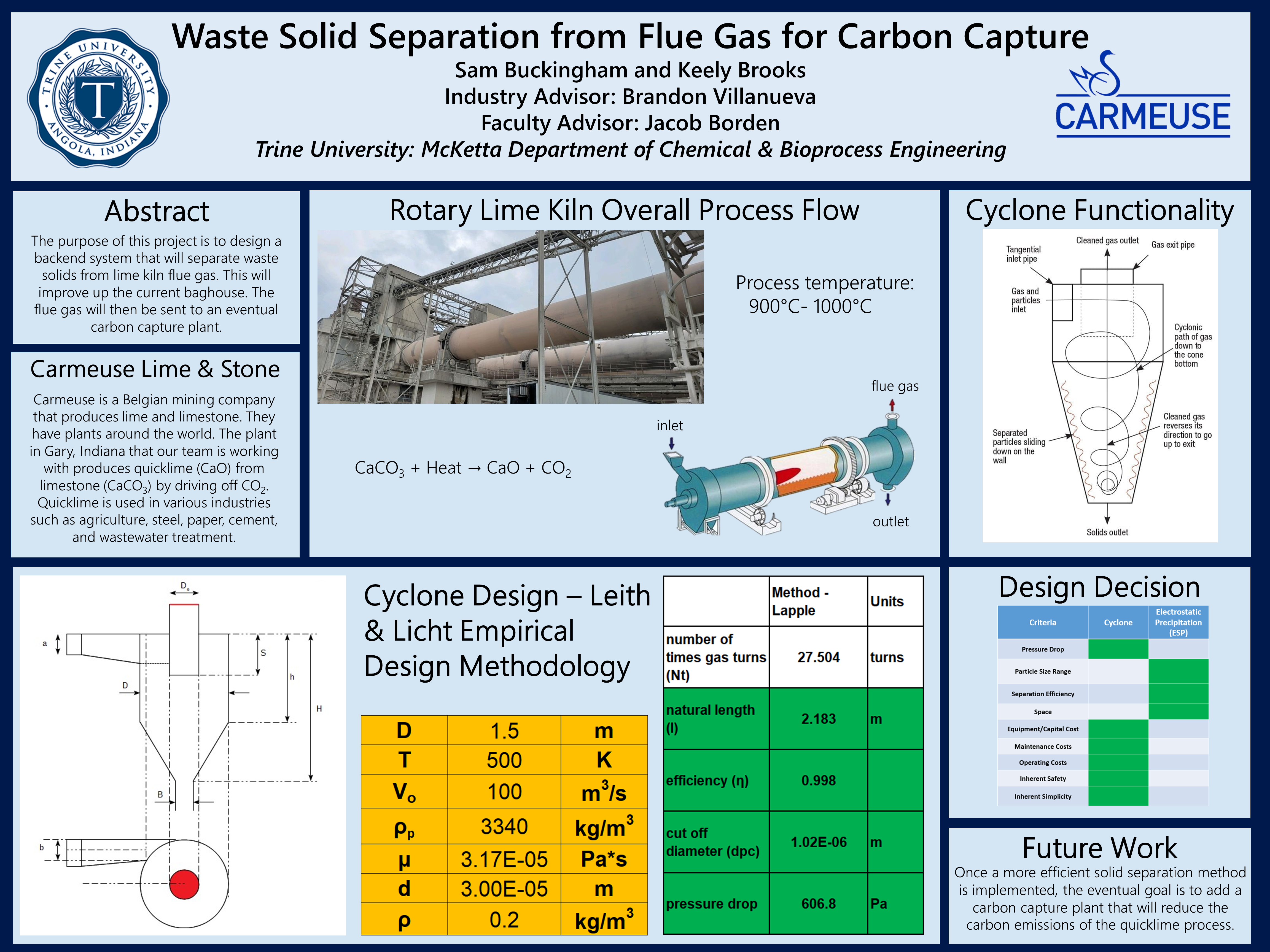

McKetta Department of Chemical and Bioprocess Engineering

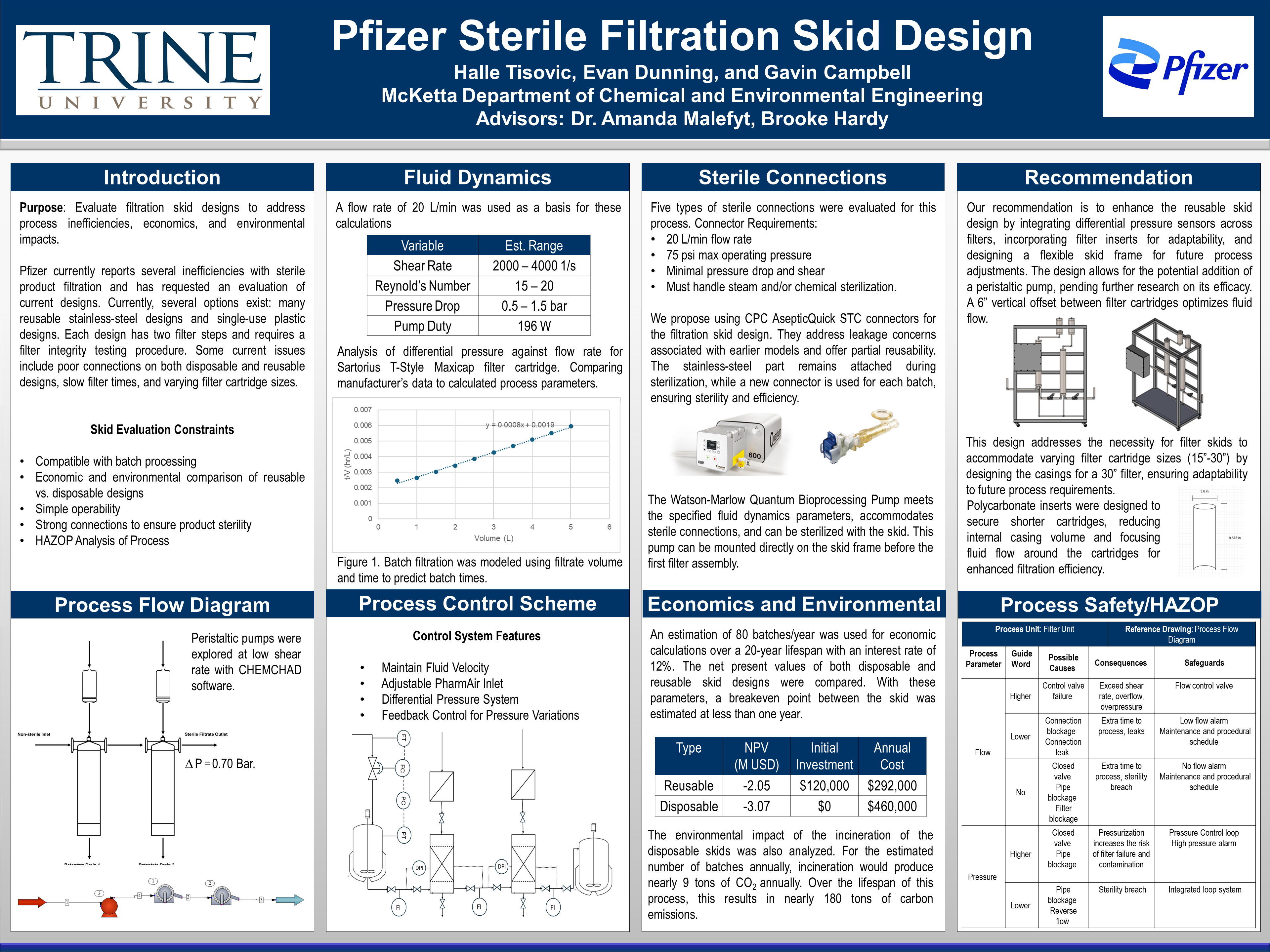

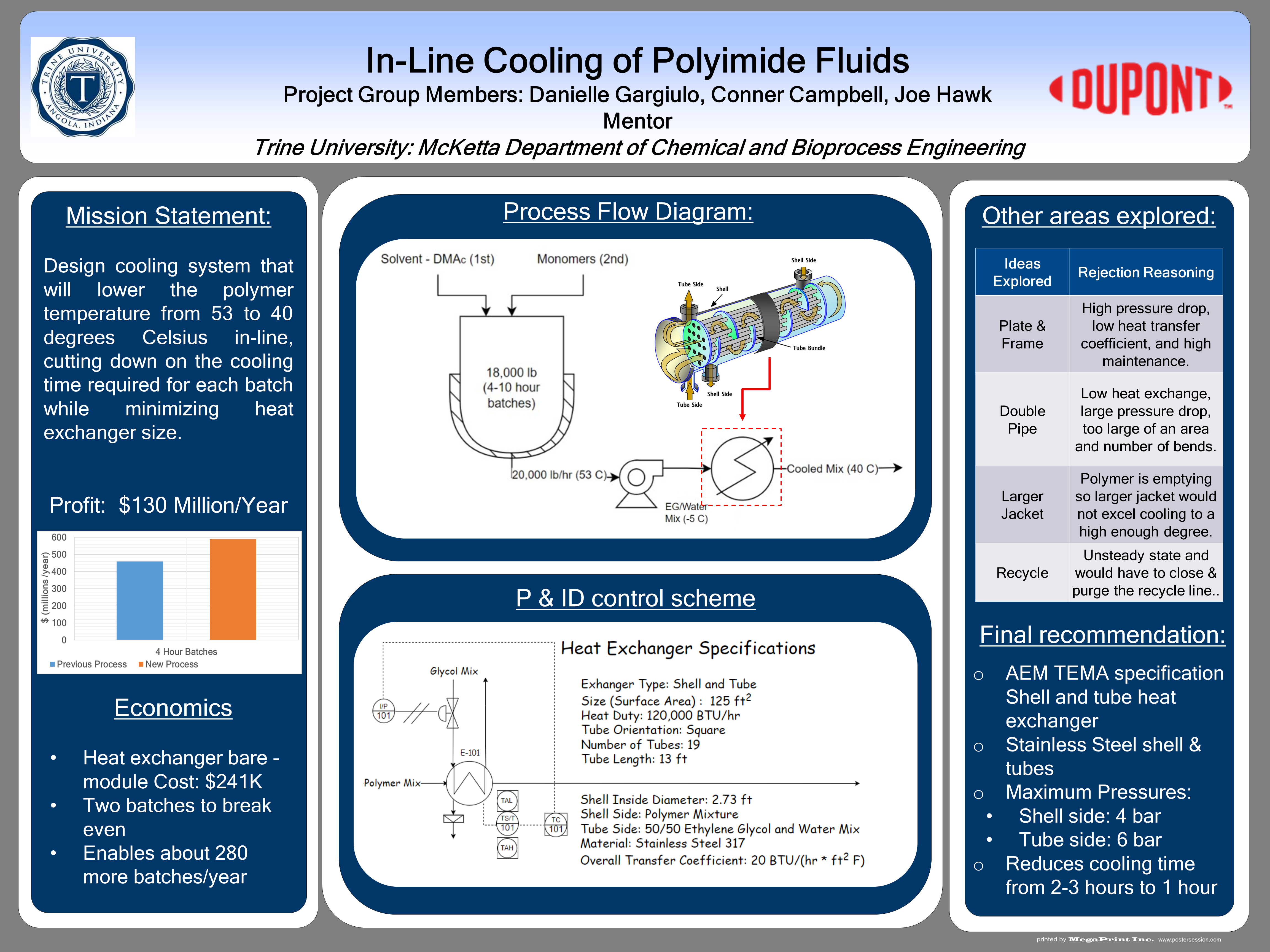

Pfizer currently reports several inefficiencies with sterile product filtration and has requested an evaluation of current designs. Currently, several options exist: many reusable stainless-steel designs and single-use plastic designs. Each design has two filter steps and requires a filter integrity testing procedure. Some current issues include poor connections on both disposable and reusable designs, slow filter times, and varying filter cartridge sizes.

Members: Halle Tisovic, Evan Dunning and Gavin Campbell

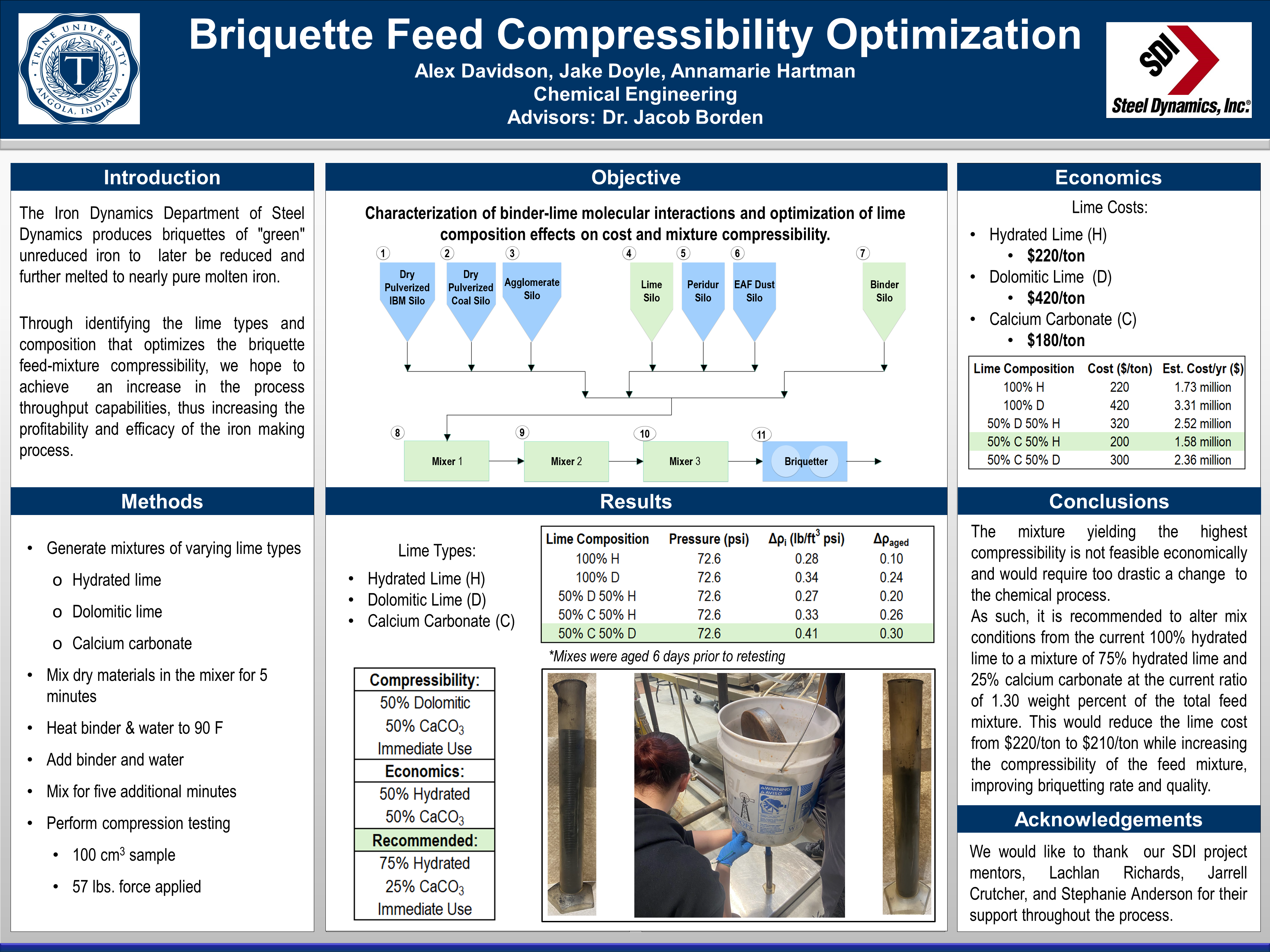

The Iron Dynamics Department of Steel Dynamics produces briquettes of "green" unreduced iron to later be reduced and further melted to nearly pure molten iron. Through identifying the lime types and composition that optimizes the briquette feed-mixture compressibility, we hope to achieve an increase in the process throughput capabilities, thus increasing the profitability and efficacy of the iron making process.

Members: Alex Davidson, Jake Doyle and Annamarie Hartman

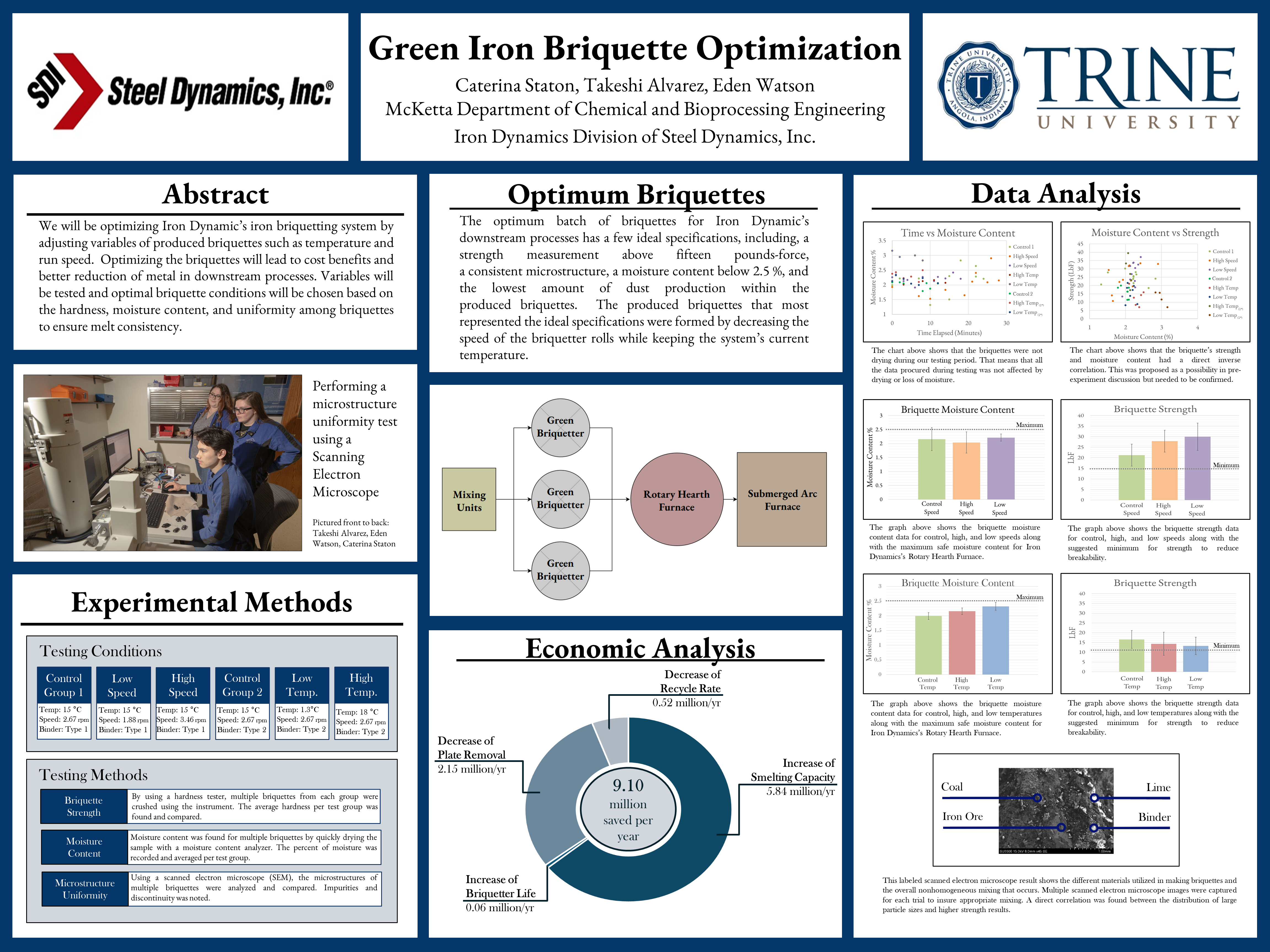

We will be optimizing Iron Dynamic’s iron briquetting system by adjusting variables of produced briquettes such as temperature and run speed. Optimizing the briquettes will lead to cost benefits and better reduction of metal in downstream processes. Variables will be tested and optimal briquette conditions will be chosen based on the hardness, moisture content, and uniformity among briquettes to ensure melt consistency.

Members: Caterina Staton, Takeshi Alvarez and Eden Watson

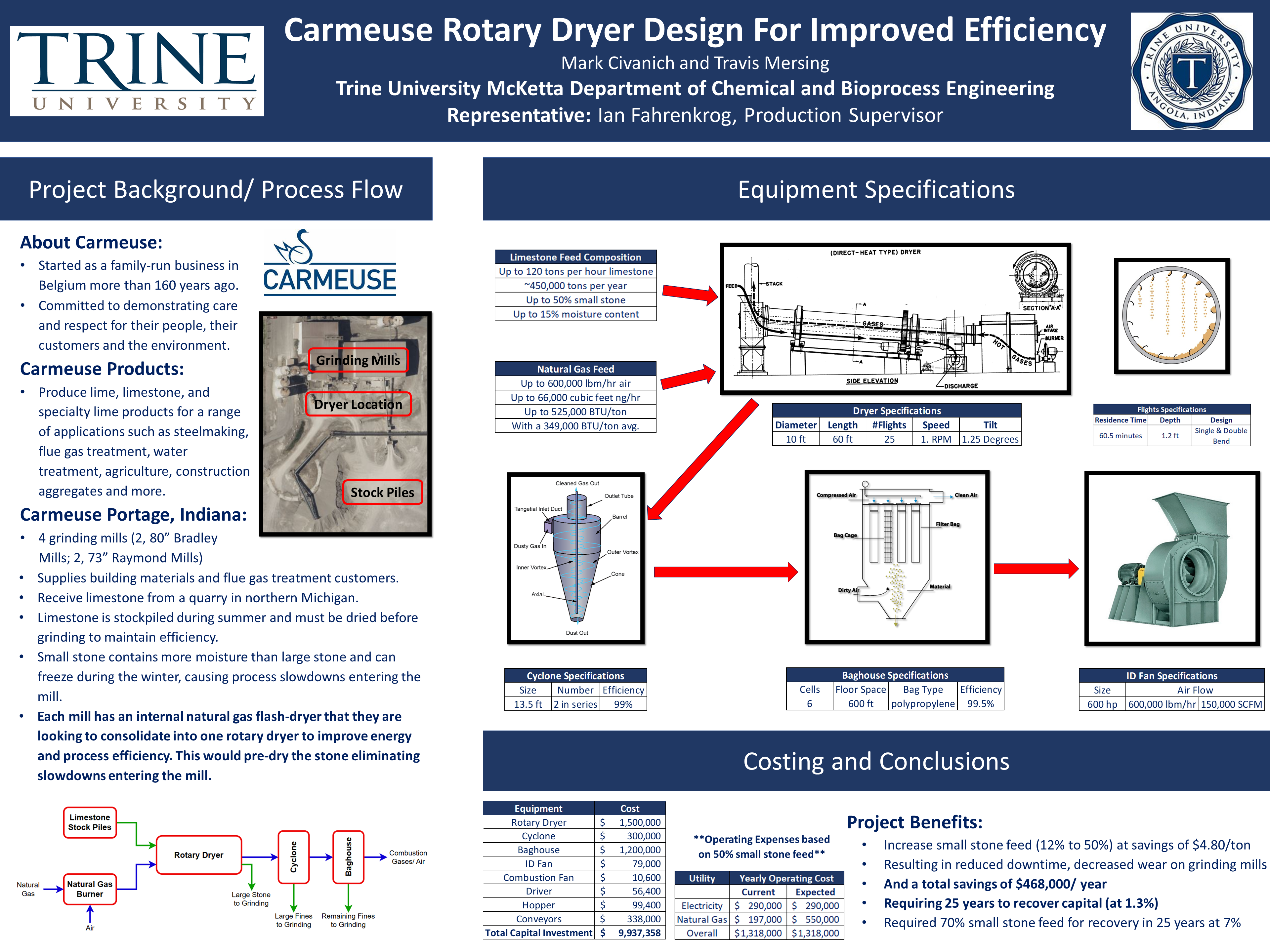

Limestone is stockpiled during summer and must be dried before grinding to maintain efficiency. Small stone contains more moisture than large stone and can freeze during the winter, causing process slowdowns entering the mill. Each mill has an internal natural gas flash-dryer that they are looking to consolidate into one rotary dryer to improve energy and process efficiency. This would pre-dry the stone eliminating slowdowns entering the mill.

Members: Mark Civanich and Travis Mersing

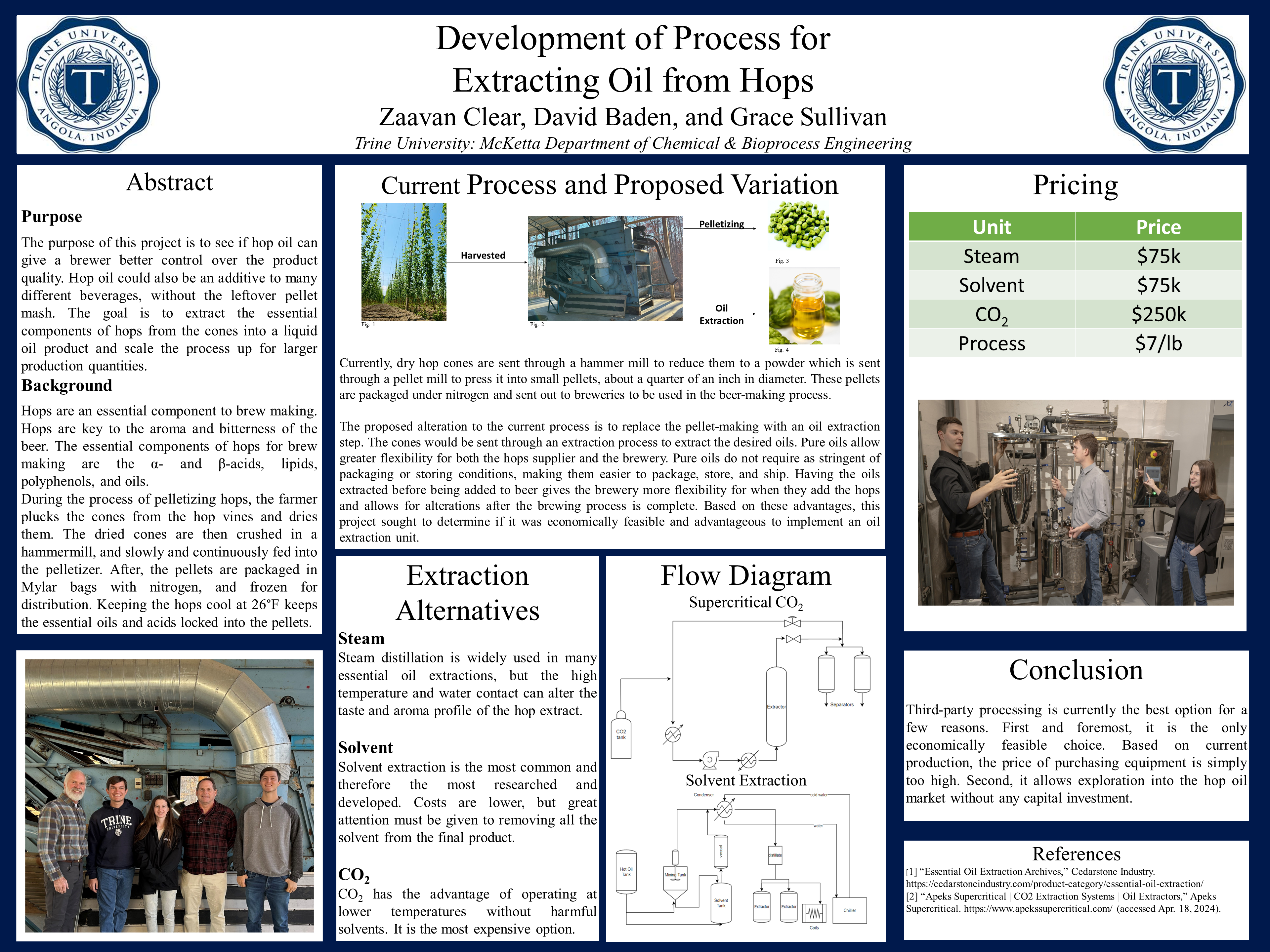

The purpose of this project is to see if hop oil can give a brewer better control over the product quality. Hop oil could also be an additive to many different beverages, without the leftover pellet mash. The goal is to extract the essential components of hops from the cones into a liquid oil product and scale the process up for larger production quantities.

Members: Zaavan Clear, David Baden and Grace Sullivan

Reiners Department of Civil and Environmental Engineering

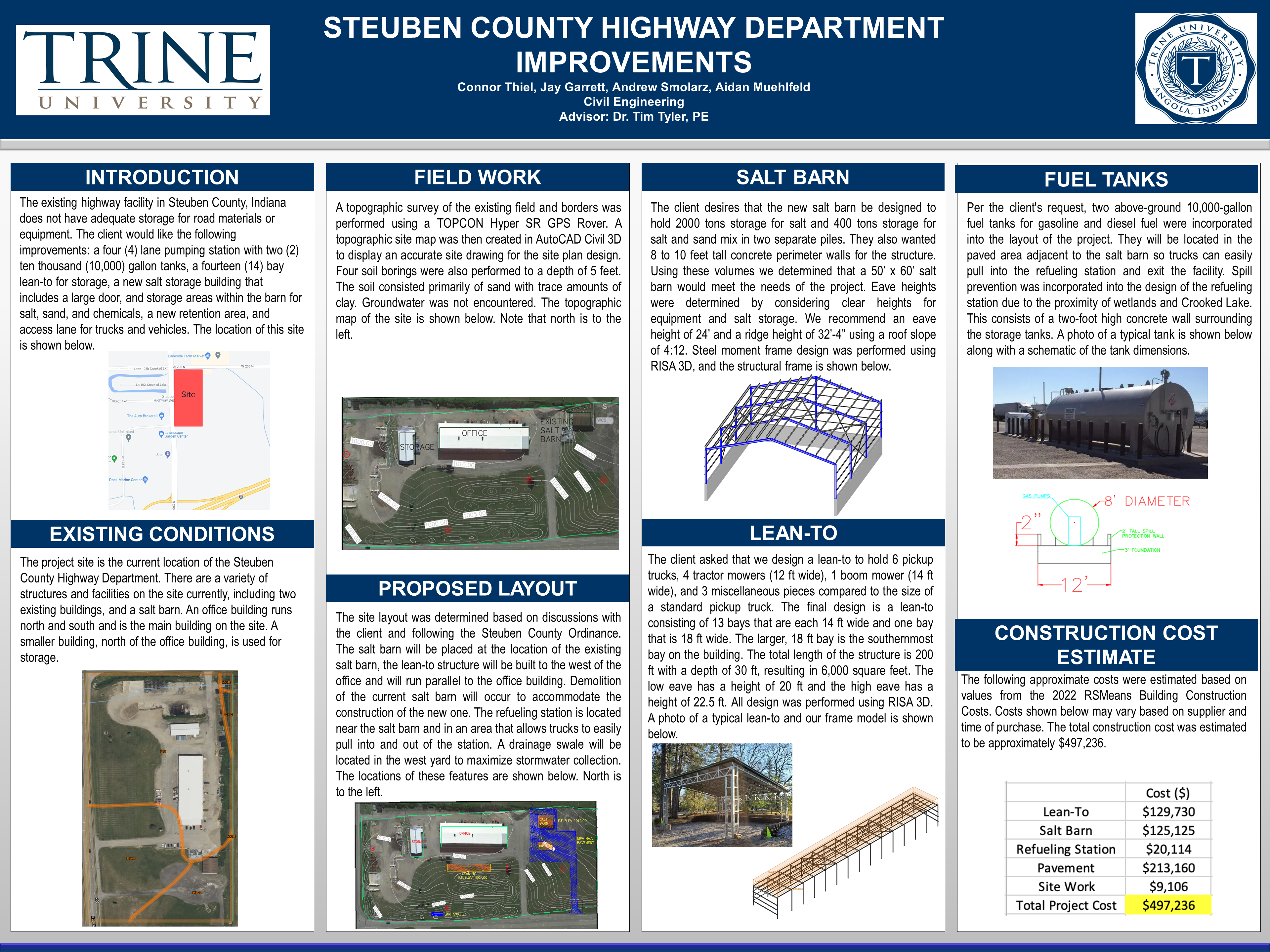

The existing highway facility in Steuben County, Indiana does not have adequate storage for road materials or equipment. The client would like the following improvements: a four (4) lane pumping station with two (2) ten thousand (10,000) gallon tanks, a fourteen (14) bay lean-to for storage, a new salt storage building that includes a large door, and storage areas within the barn for salt, sand, and chemicals, a new retention area, and access lane for trucks and vehicles. The location of this site is shown below.

Members: Conner Thiel, Jay Garrett, Andrew Smolarz and Aidan Muehlfeld

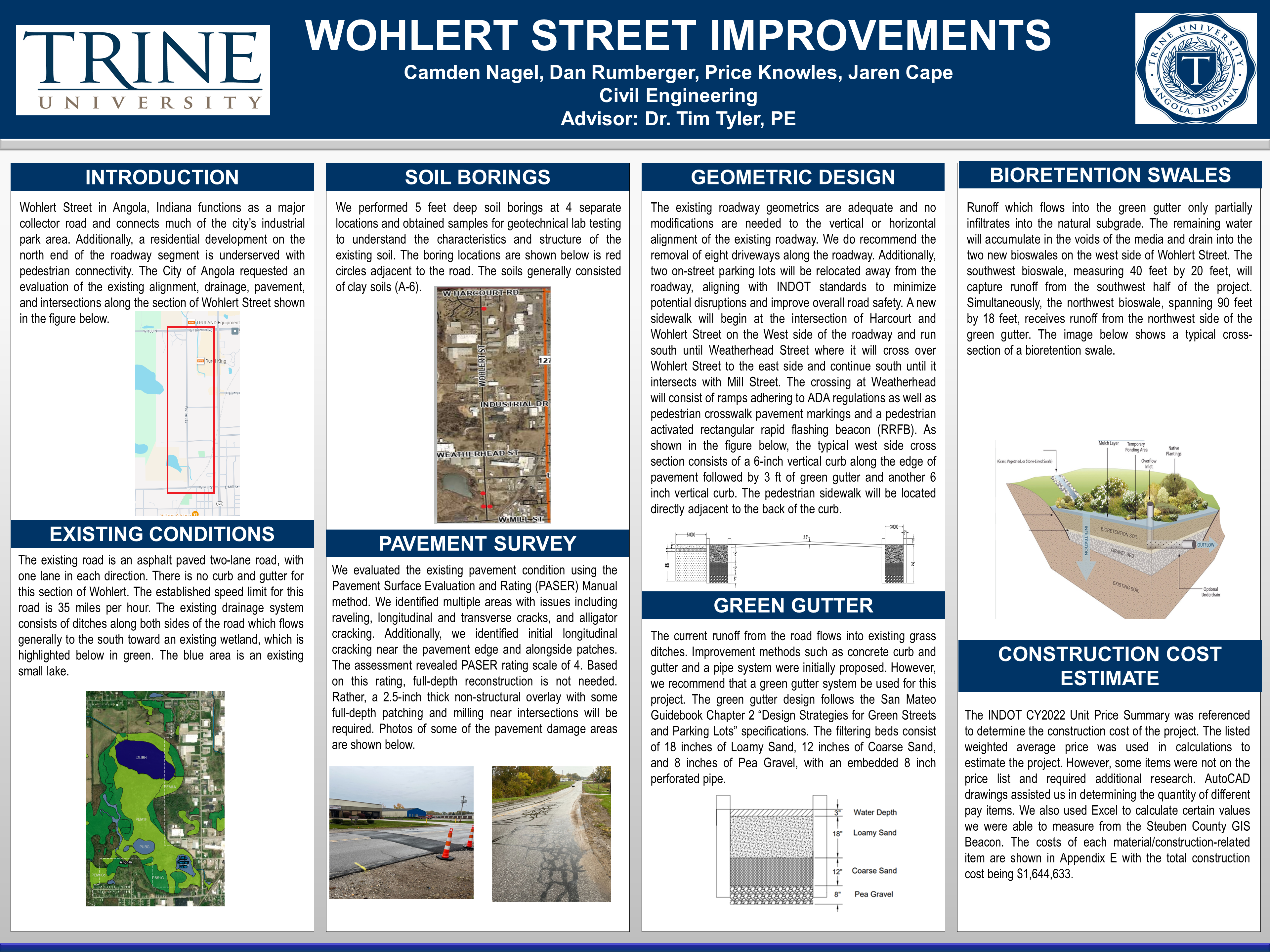

Wohlert Street in Angola, Indiana functions as a major collector road and connects much of the city’s industrial park area. Additionally, a residential development on the north end of the roadway segment is underserved with pedestrian connectivity. The City of Angola requested an evaluation of the existing alignment, drainage, pavement, and intersections along the section of Wohlert Street.

Members: Camden Nagel, Dan Rumberger, Price Knowles and Jaren Cape

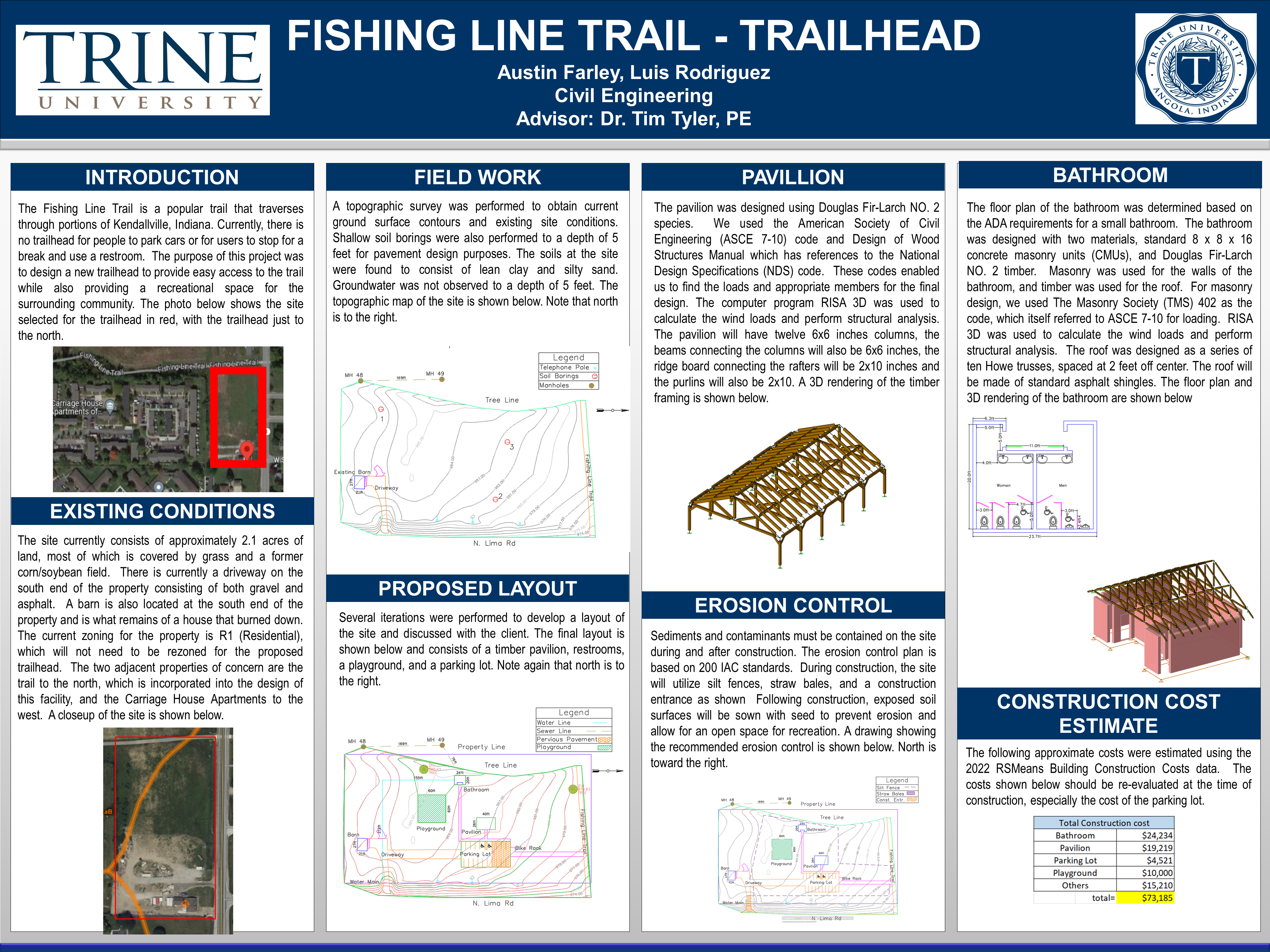

The Fishing Line Trail is a popular trail that traverses through portions of Kendallville, Indiana. Currently, there is no trailhead for people to park cars or for users to stop for a break and use a restroom. The purpose of this project was to design a new trailhead to provide easy access to the trail while also providing a recreational space for the surrounding community. The photo below shows the site selected for the trailhead in red, with the trailhead just to the north.

Members: Austin Farley and Luis Rodriguez

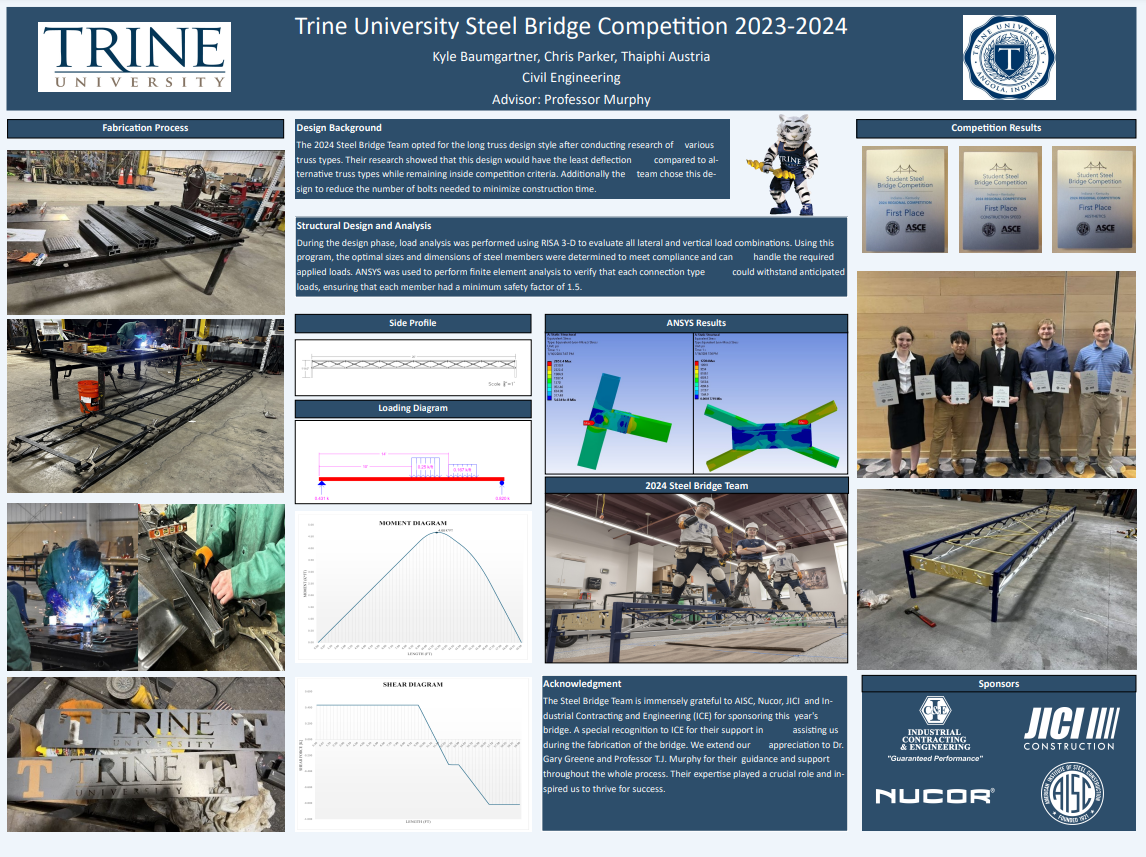

The 2024 Steel Bridge Team opted for the long truss design style after conducting research of various truss types. Their research showed that this design would have the least deflection compared to alternative truss types while remaining inside competition criteria. Additionally the team chose this design to reduce the number of bolts needed to minimize construction time.

Members: Kyle Baumgartner, Chris Parker and Thaiphi Austria

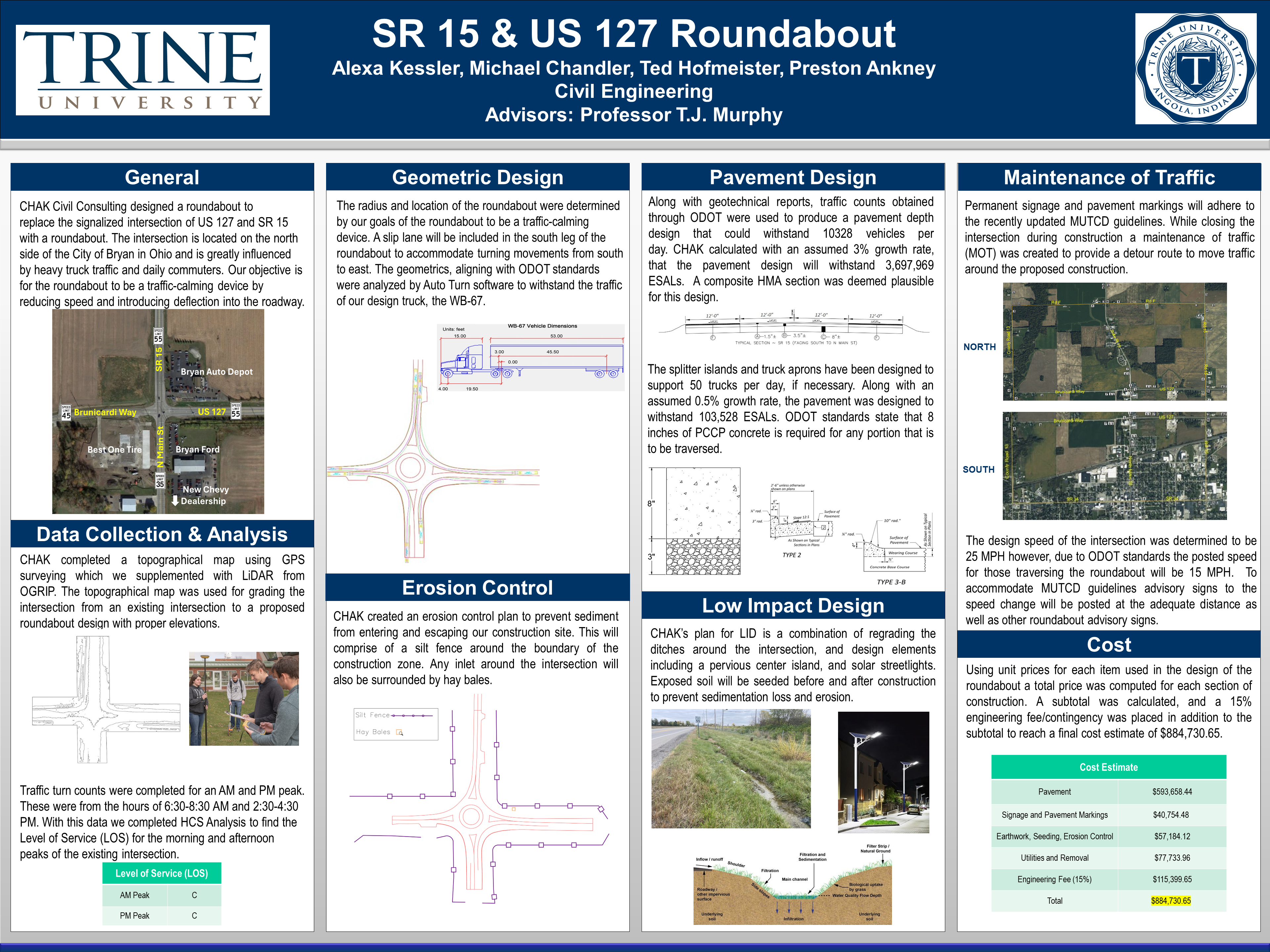

CHAK Civil Consulting designed a roundabout to replace the signalized intersection of US 127 and SR 15 with a roundabout. The intersection is located on the north side of the City of Bryan in Ohio and is greatly influenced by heavy truck traffic and daily commuters. Our objective is for the roundabout to be a traffic-calming device by reducing speed and introducing deflection into the roadway.

Members: Alexa Kessler, Michael Chandler, Ted Hofmeister and Preston Ankney

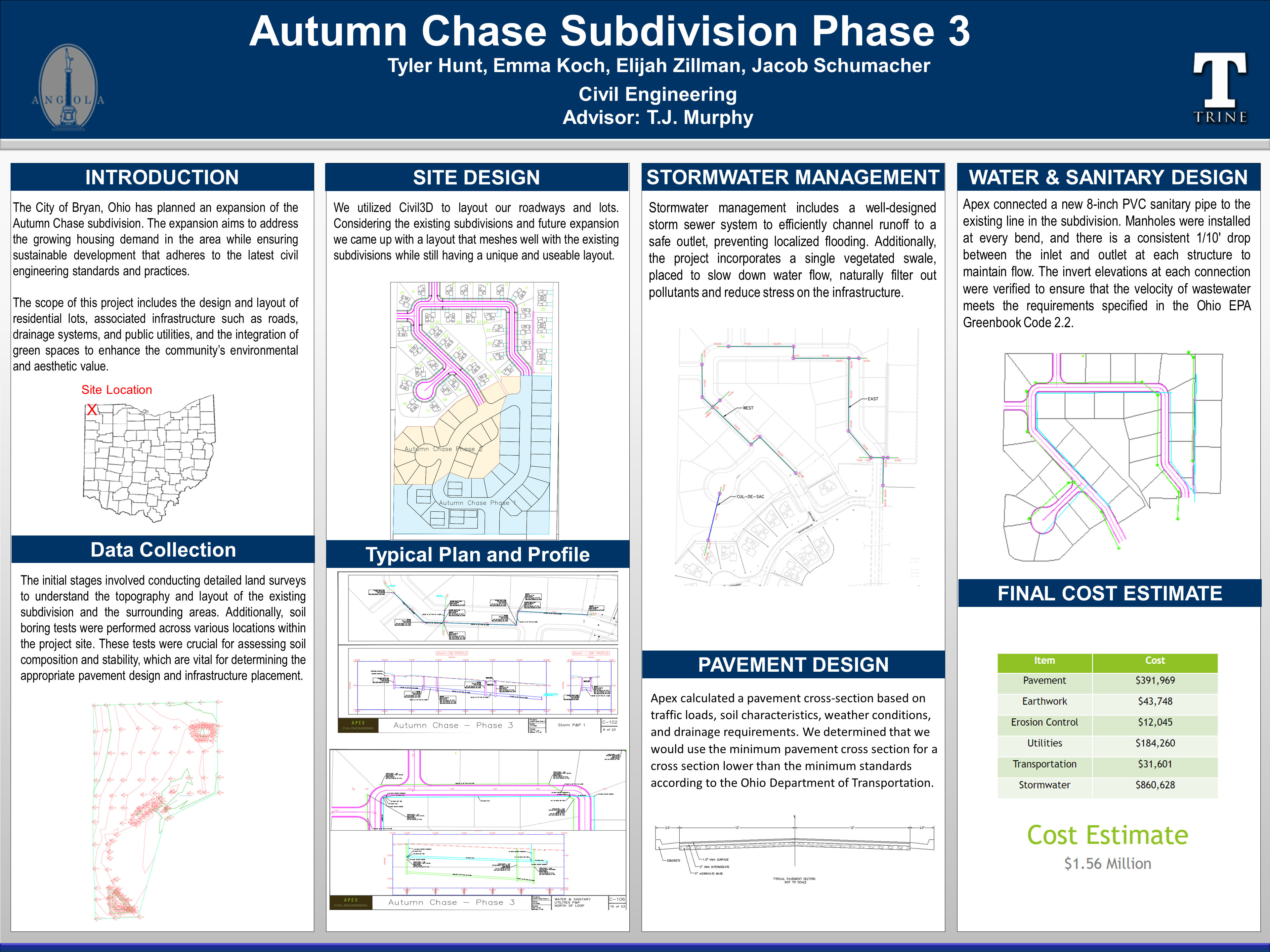

The City of Bryan, Ohio has planned an expansion of the Autumn Chase subdivision. The expansion aims to address the growing housing demand in the area while ensuring sustainable development that adheres to the latest civil engineering standards and practices.

Members: Tyler Hunt, Emma Koch, Elijah Zillman and Jacob Schumacher

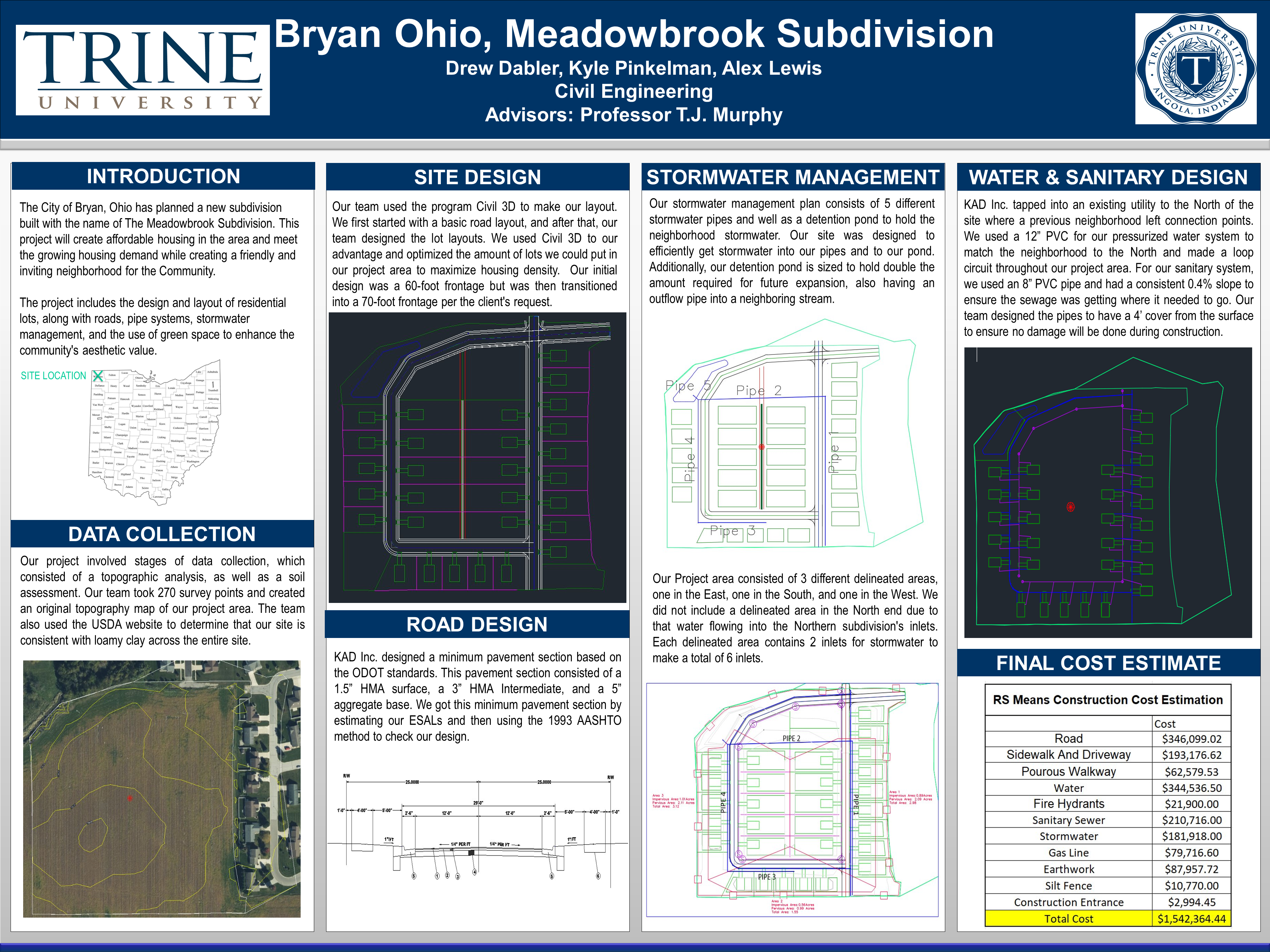

The City of Bryan, Ohio has planned a new subdivision built with the name of The Meadowbrook Subdivision. This project will create affordable housing in the area and meet the growing housing demand while creating a friendly and inviting neighborhood for the Community.

Members: Drew Dabler, Kyle Pinkelman and Alex Lewis

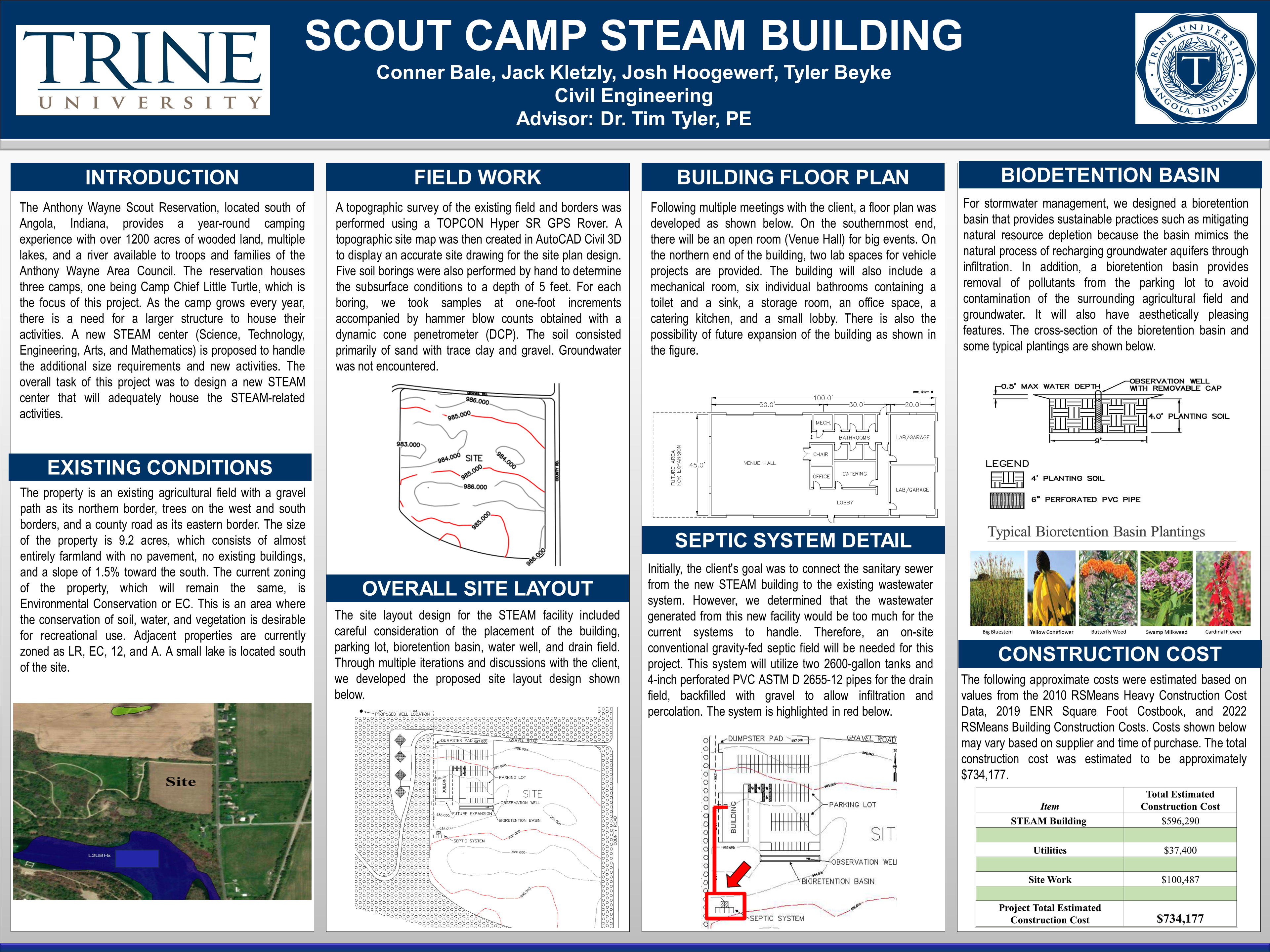

The Anthony Wayne Scout Reservation, located south of Angola, Indiana, provides a year-round camping experience with over 1200 acres of wooded land, multiple lakes, and a river available to troops and families of the Anthony Wayne Area Council. The reservation houses three camps, one being Camp Chief Little Turtle, which is the focus of this project. As the camp grows every year, there is a need for a larger structure to house their activities. A new STEAM center (Science, Technology, Engineering, Arts, and Mathematics) is proposed to handle the additional size requirements and new activities. The overall task of this project was to design a new STEAM center that will adequately house the STEAM-related activities.

Members: Conner Bale, Jack Kletzly, Josh Hoogewerf and Tyler Beyke

Department of Computer Science and Information Technology

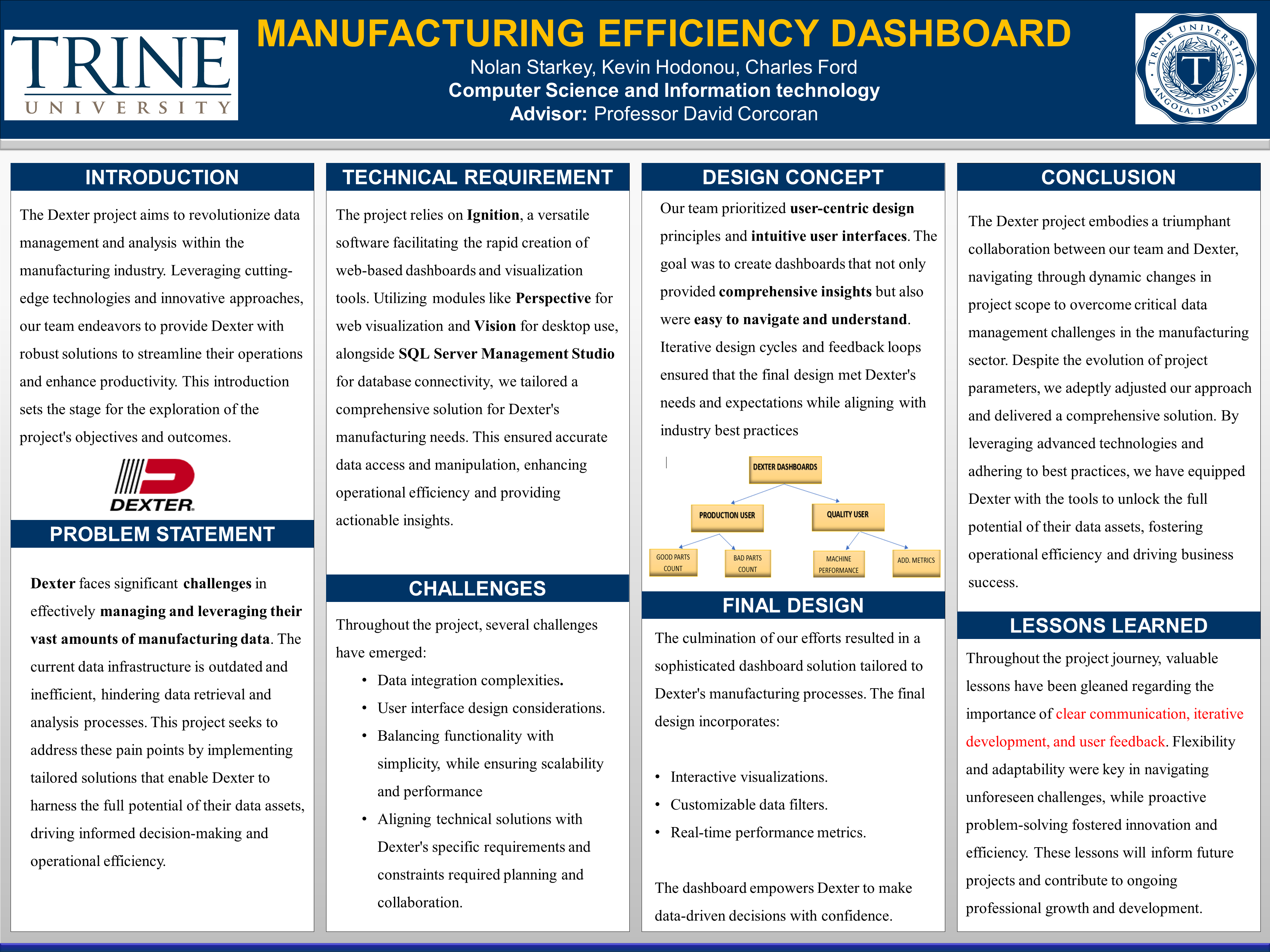

The Dexter project aims to revolutionize data management and analysis within the manufacturing industry. Leveraging cutting-edge technologies and innovative approaches, our team endeavors to provide Dexter with robust solutions to streamline their operations and enhance productivity.

Members: Nolan Starkey, Kevin Hodonou and Charles Ford

Department of Design Engineering Technology

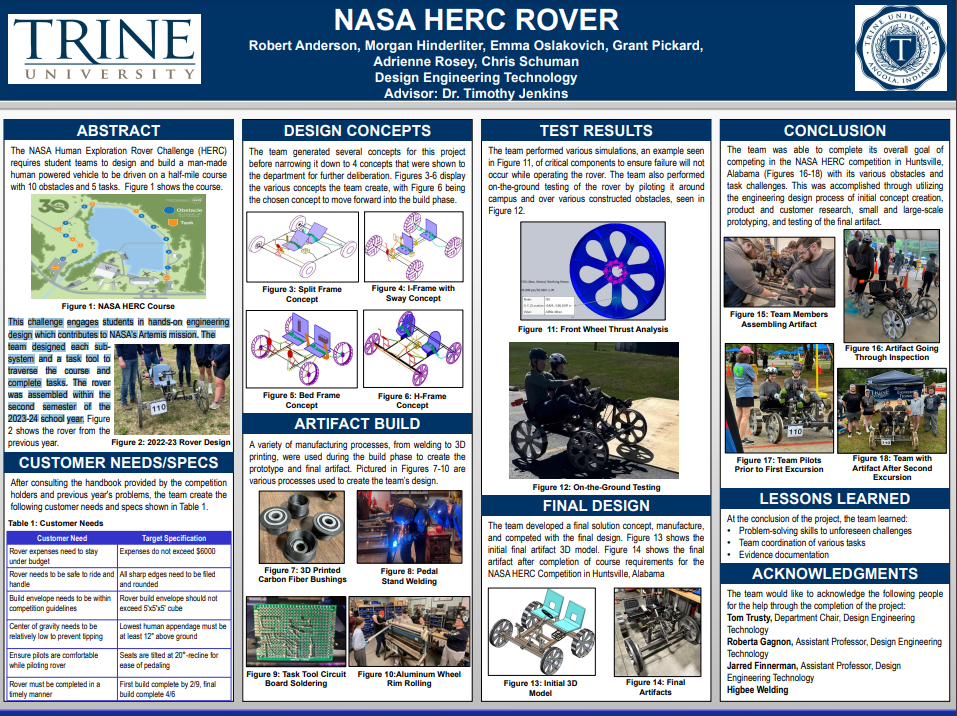

The NASA Human Exploration Rover Challenge (HERC) requires student teams to design and build a man-made human powered vehicle to be driven on a half-mile course with 10 obstacles and 5 tasks. This challenge engages students in hands-on engineering design which contributes to NASA’s Artemis mission. The team designed each subsystem and a task tool to traverse the course and complete tasks. The rover was assembled within the second semester of the 2023-24 school year.

Members: Robert Anderson, Morgan Hinderliter, Emma Oslakovich, Grant Pickard, Adrienne Rosey and Chris Schuman

Mr. Brandon Cathy, a previous Trine DET student, tasked the team with designing a device that could be able to effectively allow for 6-10 medical grade parts to be sand blasted in the same chamber without allowing any part-to-part contact or overspray. Originally, Mr Cathy viewed this project to take the form of a rotary table that be fit within the sandblaster and be rotated externally via possible electronic connections. The way the company was transporting and sandblasting the product was with what was effectively a baking sheet that had all the parts on it and just took the parts to the sand blaster and sprayed the whole thing, leading to parts

touching each other and over spray on already sprayed parts. The team started with designing several concepts involving a rotary table, however the team had another idea. Taking into consideration what the sand blaster operator

already did, the team designed a tray that not only met all the customer needs and specifications, but also did not change what the operator were already accustomed to. With

Mr Cathy's permission, the team developed the tray concept further into a final prototype.

Members: Will Holle, Conner Johnson, Martin Moyer and William Neely

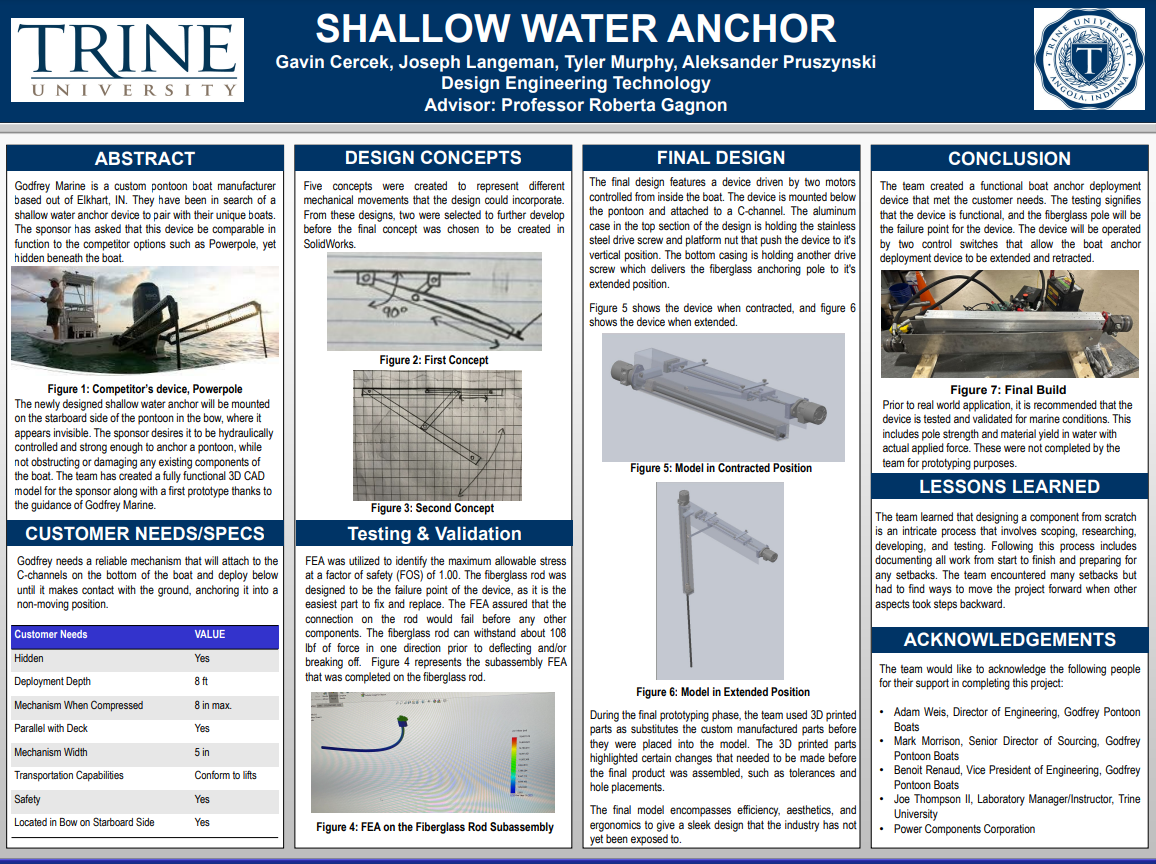

Godfrey Marine is a custom pontoon boat manufacturer based out of Elkhart, IN. They

have been in search of a shallow water anchor device to pair with their unique boats.

The sponsor has asked that this device be comparable in function to the competitor

options such as Powerpole, yet

hidden beneath the boat.

Members: Gavin Cercek, Joseph Langeman, Tyler Murphy and Aleksander Pruszynski

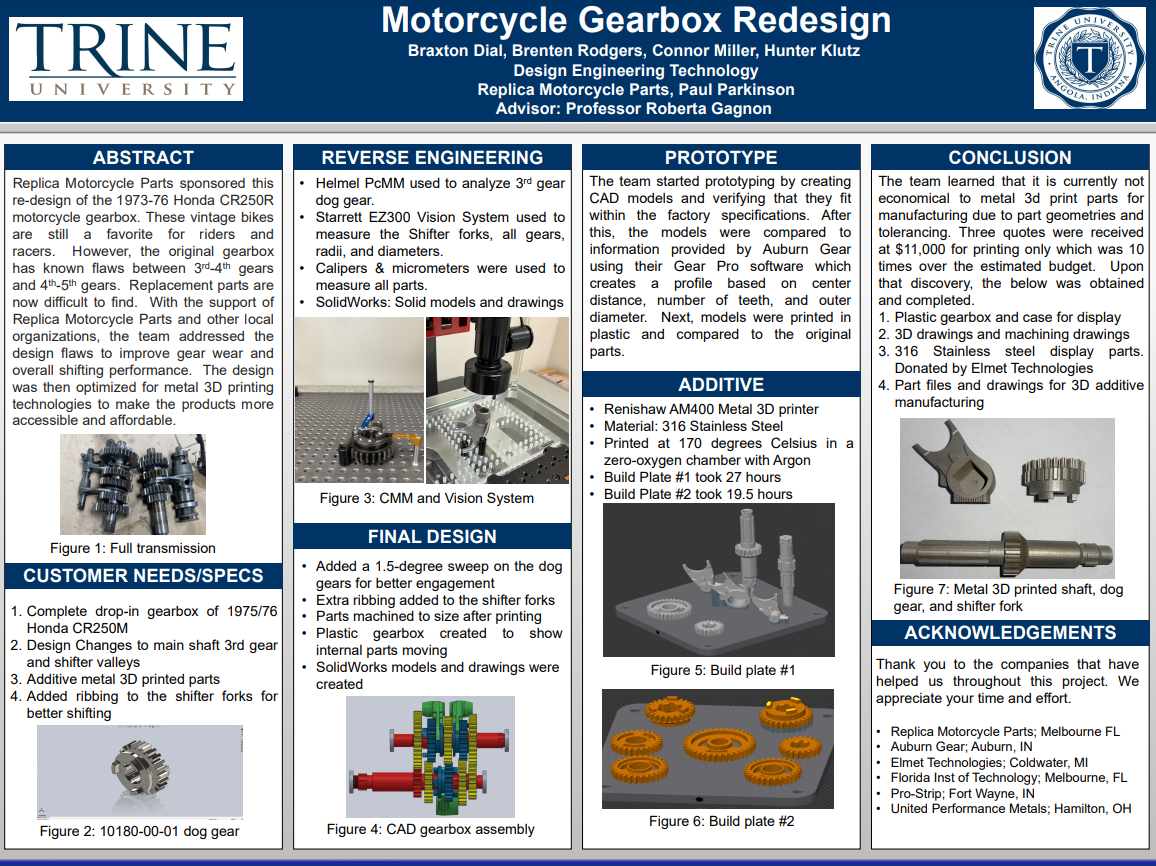

Replica Motorcycle Parts sponsored this re-design of the 1973-76 Honda CR250R motorcycle

gearbox. These vintage bikes are still a favorite for riders and racers. However,

the original gearbox has known flaws between 3rd-4th gears and 4th-5th gears. Replacement

parts are now difficult to find. With the support of Replica Motorcycle Parts and

other local organizations, the team addressed the design flaws to improve gear wear

and overall shifting performance. The design was then optimized for metal 3D printing

technologies to make the products more accessible and affordable.

Members: Braxton Dial, Brenten Rodgers, Conner Miller and Hunter Klutz

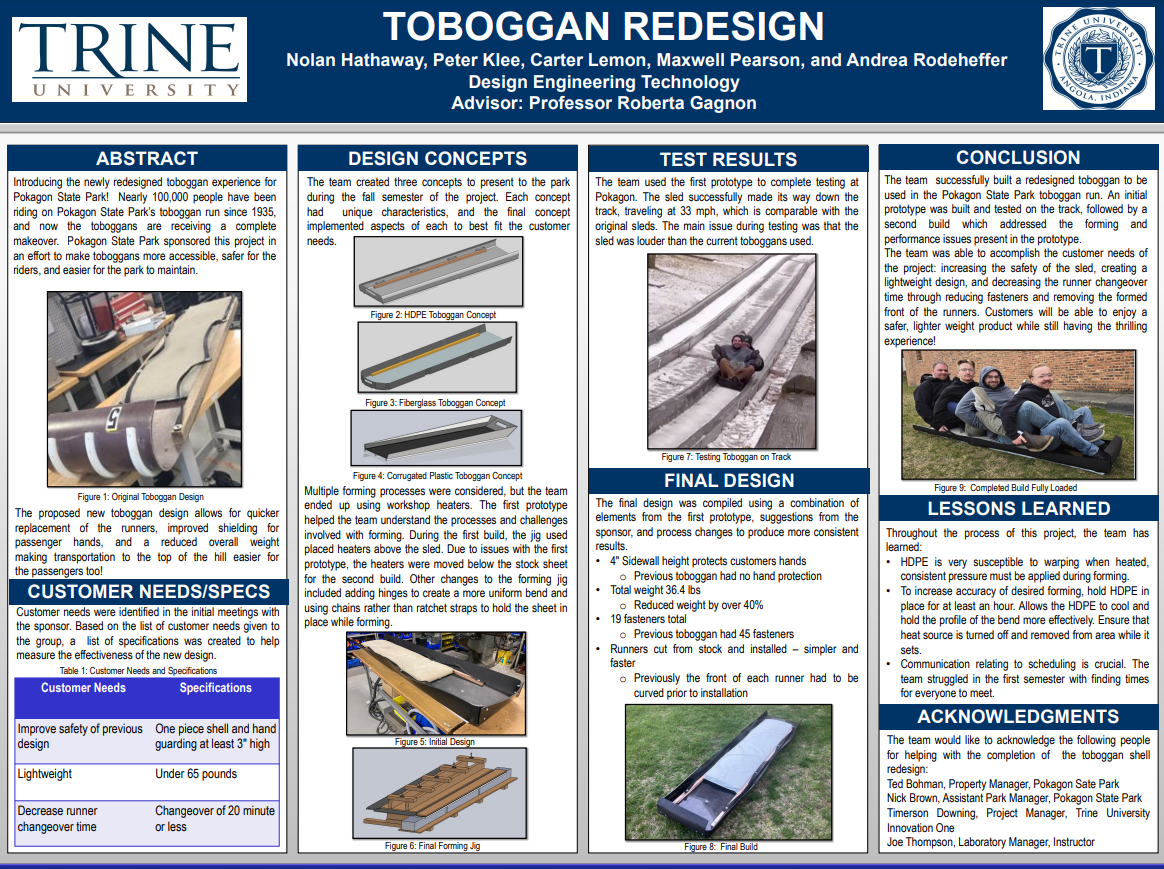

Introducing the newly redesigned toboggan experience for Pokagon State Park! Nearly 100,000 people have been riding on Pokagon State Park’s toboggan run since 1935, and now the toboggans are receiving a complete makeover. Pokagon State Park sponsored this project in an effort to make toboggans more accessible, safer for the riders, and easier for the park to maintain.

Members: Nolan Hathaway, Peter Klee, Carter Lemon, Maxwell Pearson and Andrea Rodeheffer

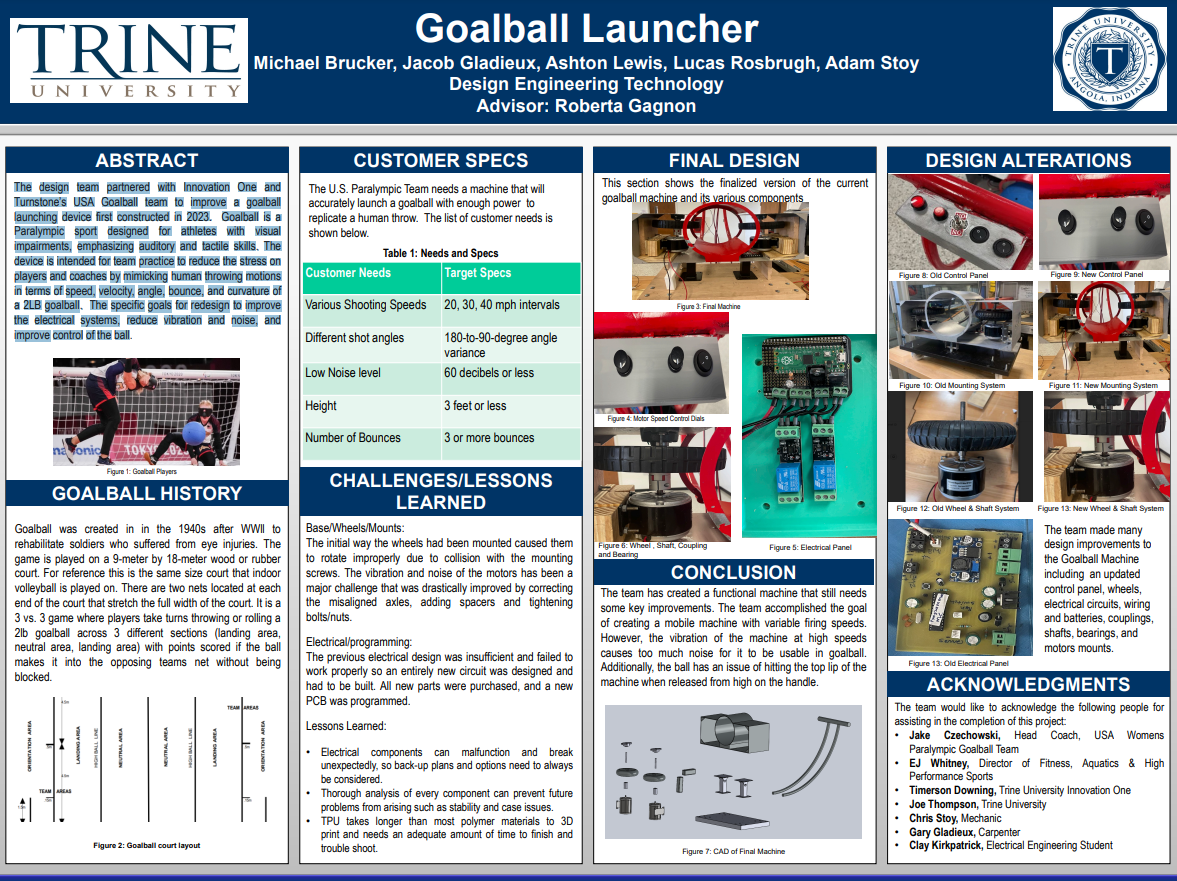

The design team partnered with Innovation One and Turnstone’s USA Goalball team to improve a goalball launching device first constructed in 2023. Goalball is a Paralympic sport designed for athletes with visual impairments, emphasizing auditory and tactile skills. The device is intended for team practice to reduce the stress on players and coaches by mimicking human throwing motions in terms of speed, velocity, angle, bounce, and curvature of a 2LB goalball. The specific goals for redesign to improve the electrical systems, reduce vibration and noise, and improve control of the ball.

Members: Michael Brucker, Jacob Gladieux, Ashton Lewis, Lucas Rosbrugh and Adam Stoy

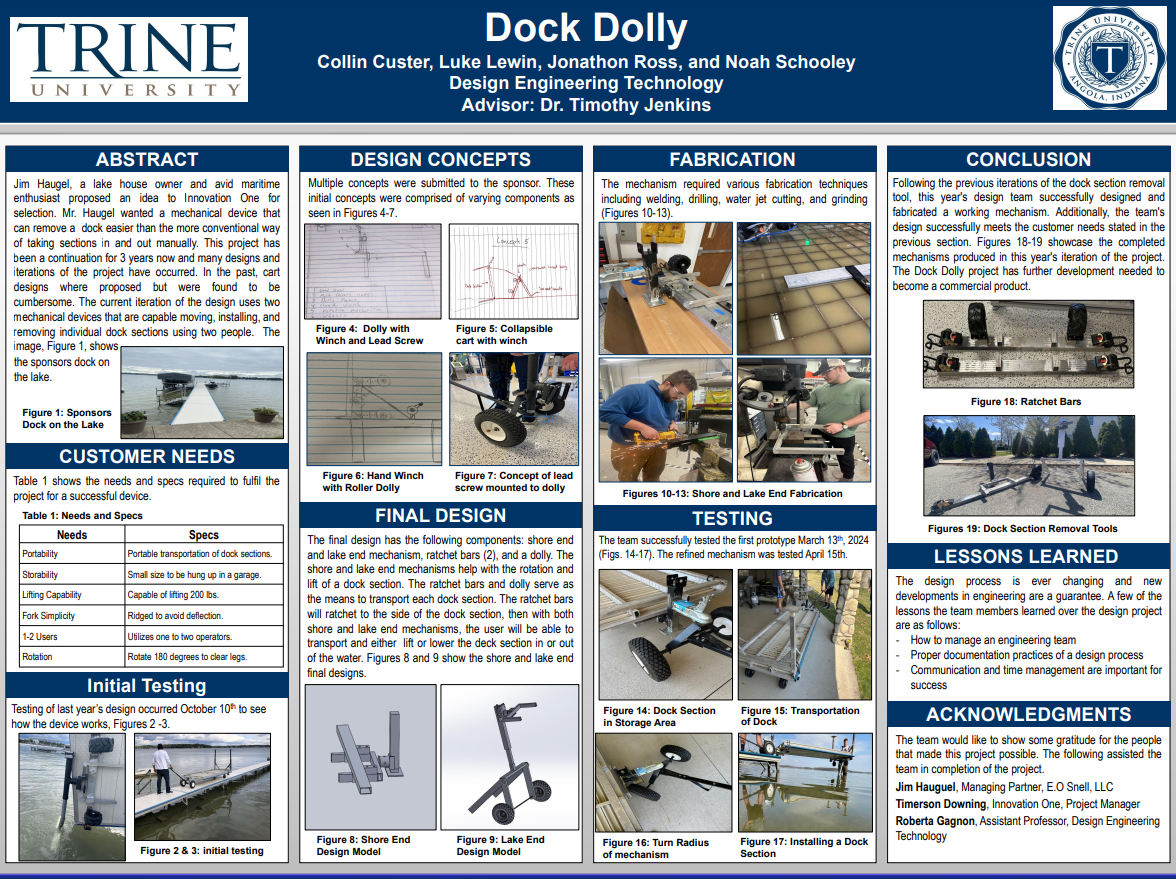

Jim Haugel, a lake house owner and avid maritime enthusiast proposed an idea to Innovation

One for selection. Mr. Haugel wanted a mechanical device that can remove a dock easier

than the more conventional way of taking sections in and out manually. This project

has

been a continuation for 3 years now and many designs and iterations of the project

have occurred. In the past, cart designs where proposed but were found to be cumbersome.

The current iteration of the design uses two mechanical devices that are capable moving,

installing, and removing individual dock sections using two people. The image, Figure

1, shows the sponsors dock on the lake.

Members: Collin Custer, Luke Lewin, Jonathan Ross and Noah Schooley

Hendrickson is a leading manufacturer in suspension systems components for heavy trucks and the sponsor for the Metal Shavings Shredder project. The tube cutting process that Hendrickson uses, produces metal shavings that are a waste of time and space for the organization and dangerous to handle by hand (Figure 1). Hendrickson has the goal of limiting this with a metal shredder. The shredder will reduce the shavings to a much safer and manageable size for the operators and will save Hendrickson time and money in the long run being there will be less time and money spent ridding of the metal shavings. With this project being a continuation of a previous team, the current team was tasked with improving certain areas of the machine and getting the project to a functioning and safe state for Hendrickson. Figure 2 shows the beginning state of the machine for the team with a frame, shredding box, electrical box, motor, and gearbox.

Members: Anna Dressler, Matthew Crawford, Matthew Shoemaker and Hunter Smith

Department of Electrical and Computer Engineering

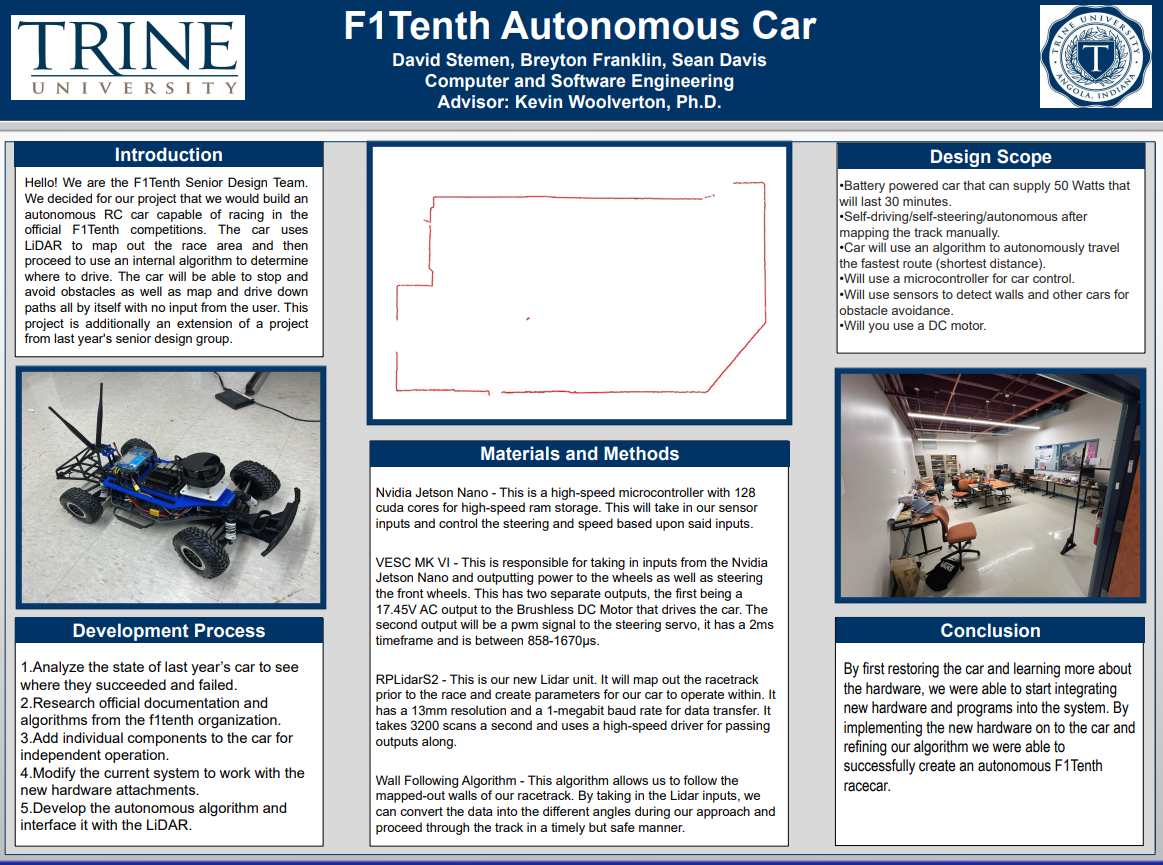

We are the F1Tenth Senior Design Team. We decided for our project that we would build an autonomous RC car capable of racing in the official F1Tenth competitions. The car uses LiDAR to map out the race area and then proceed to use an internal algorithm to determine where to drive. The car will be able to stop and avoid obstacles as well as map and drive down paths all by itself with no input from the user. This project is additionally an extension of a project from last year's senior design group.

Members: David Stemen, Breyton Franklin and Sean Davis

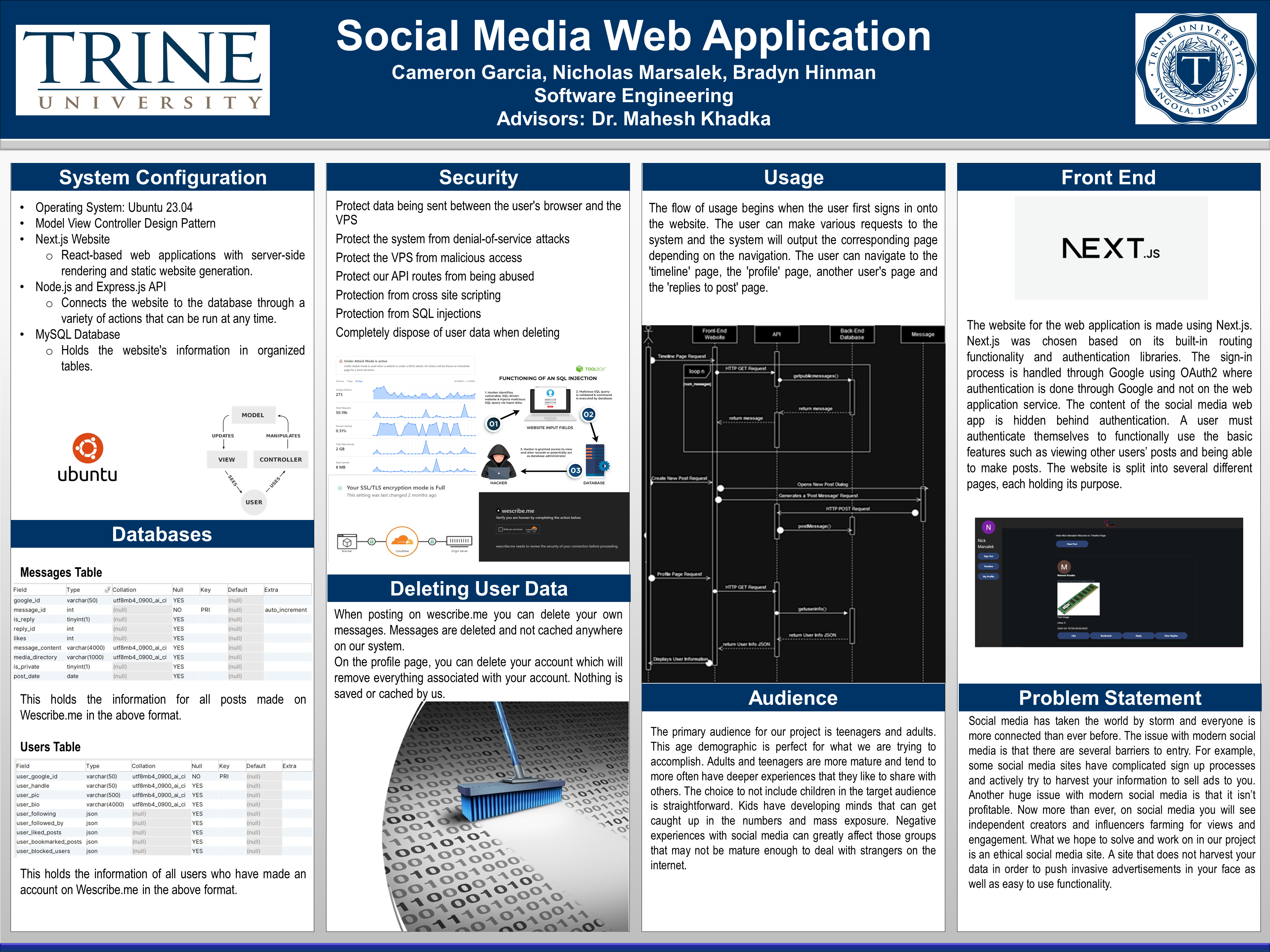

Social media has taken the world by storm and everyone is more connected than ever before. The issue with modern social media is that there are several barriers to entry. For example, some social media sites have complicated sign up processes and actively try to harvest your information to sell ads to you. Another huge issue with modern social media is that it isn’t profitable. Now more than ever, on social media you will see independent creators and influencers farming for views and engagement. What we hope to solve and work on in our project is an ethical social media site. A site that does not harvest your data in order to push invasive advertisements in your face as well as easy to use functionality.

Members: Cameron Garcia, Nicholas Marsalek and Brayden Hinman

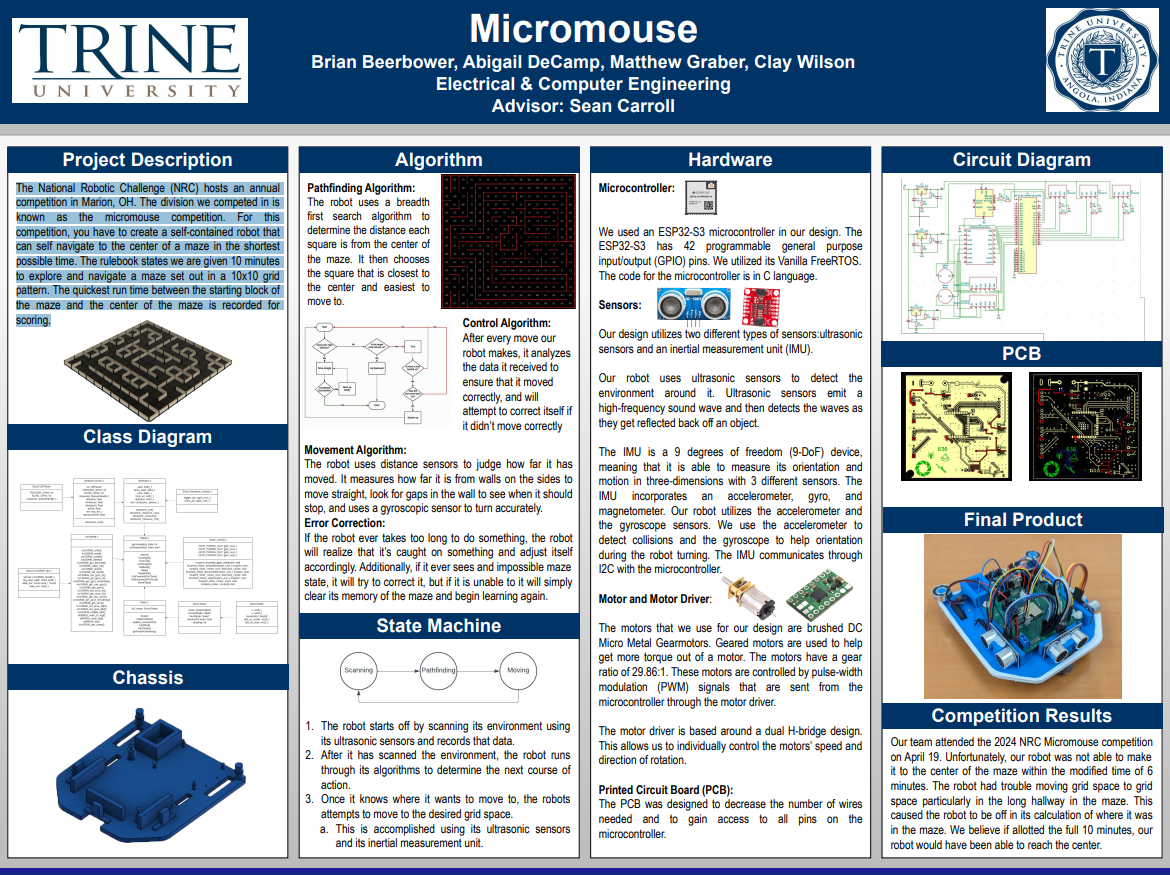

The National Robotic Challenge (NRC) hosts an annual competition in Marion, OH. The division we competed in is known as the micromouse competition. For this competition, you have to create a self-contained robot that can self navigate to the center of a maze in the shortest

possible time. The rulebook states we are given 10 minutes to explore and navigate a maze set out in a 10x10 grid pattern. The quickest run time between the starting block of the maze and the center of the maze is recorded for scoring.

Members: Brian Beerbower, Abigail DeCamp, Matthew Graber and Clay Wilson

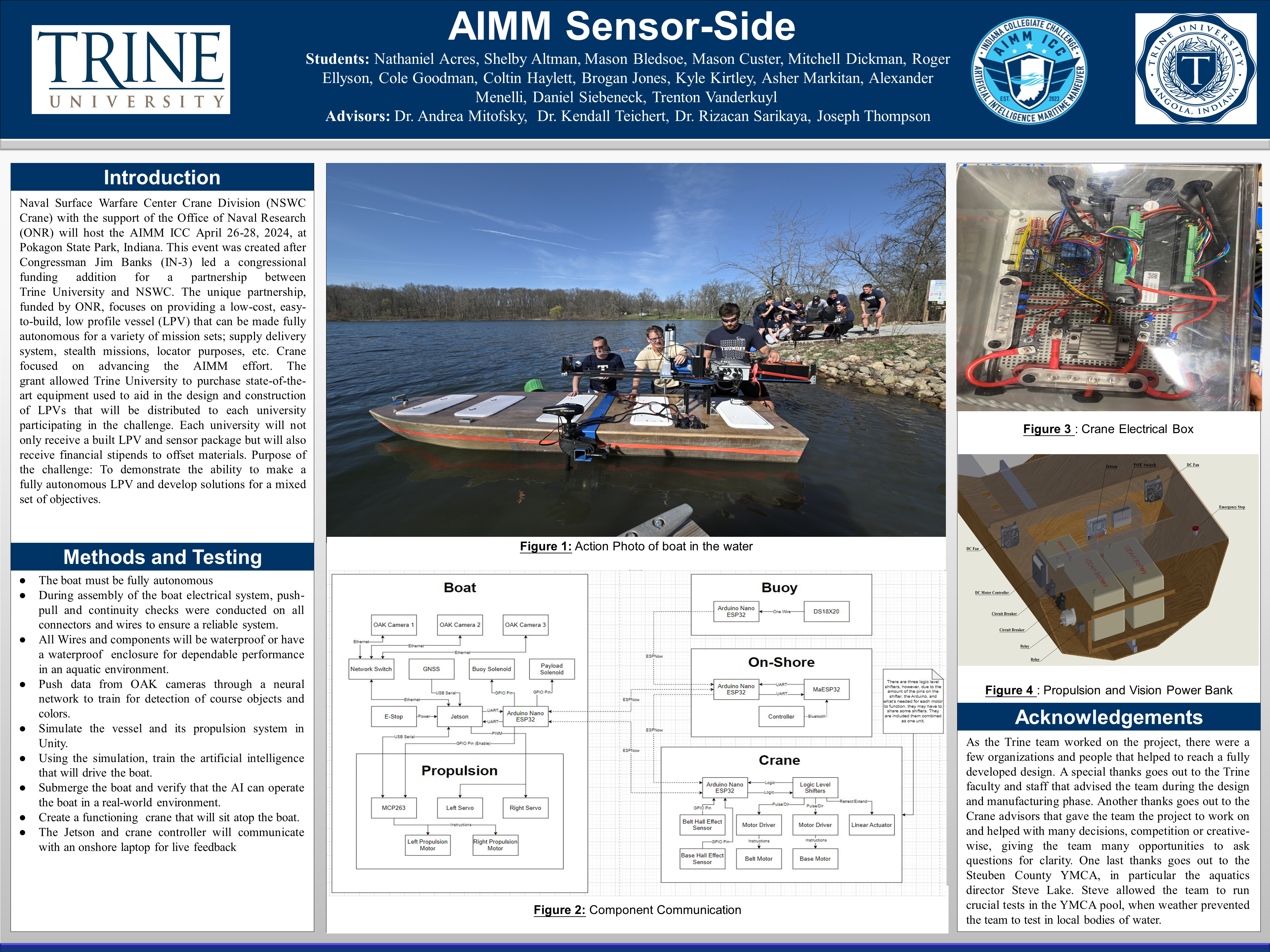

Naval Surface Warfare Center Crane Division (NSWC Crane) with the support of the Office of Naval Research (ONR) will host the AIMM ICC April 26-28, 2024, at Pokagon State Park, Indiana. This event was created after Congressman Jim Banks (IN-3) led a congressional funding addition for a partnership between Trine University and NSWC. The unique partnership, funded by ONR, focuses on providing a low-cost, easy-to-build, low profile vessel (LPV) that can be made fully autonomous for a variety of mission sets; supply delivery system, stealth missions, locator purposes, etc. Crane focused on advancing the AIMM effort. The grant allowed Trine University to purchase state-of-the-art equipment used to aid in the design and construction of LPVs that will be distributed to each university participating in the challenge. Each university will not only receive a built LPV and sensor package but will also receive financial stipends to offset materials. Purpose of the challenge: To demonstrate the ability to make a fully autonomous LPV and develop solutions for a mixed set of objectives.

Members: Nathaniel Acres, Shelby Altman, Mason Bledsoe, Mason Custer, Mitchell Dickman, Roger Ellyson, Cole Goodman, Coltin Haylett, Brogan Jones, Kyle Kirtley, Asher Markitan, Alexander Menelli, Daniel Siebeneck and Trenton Vanderkuyl

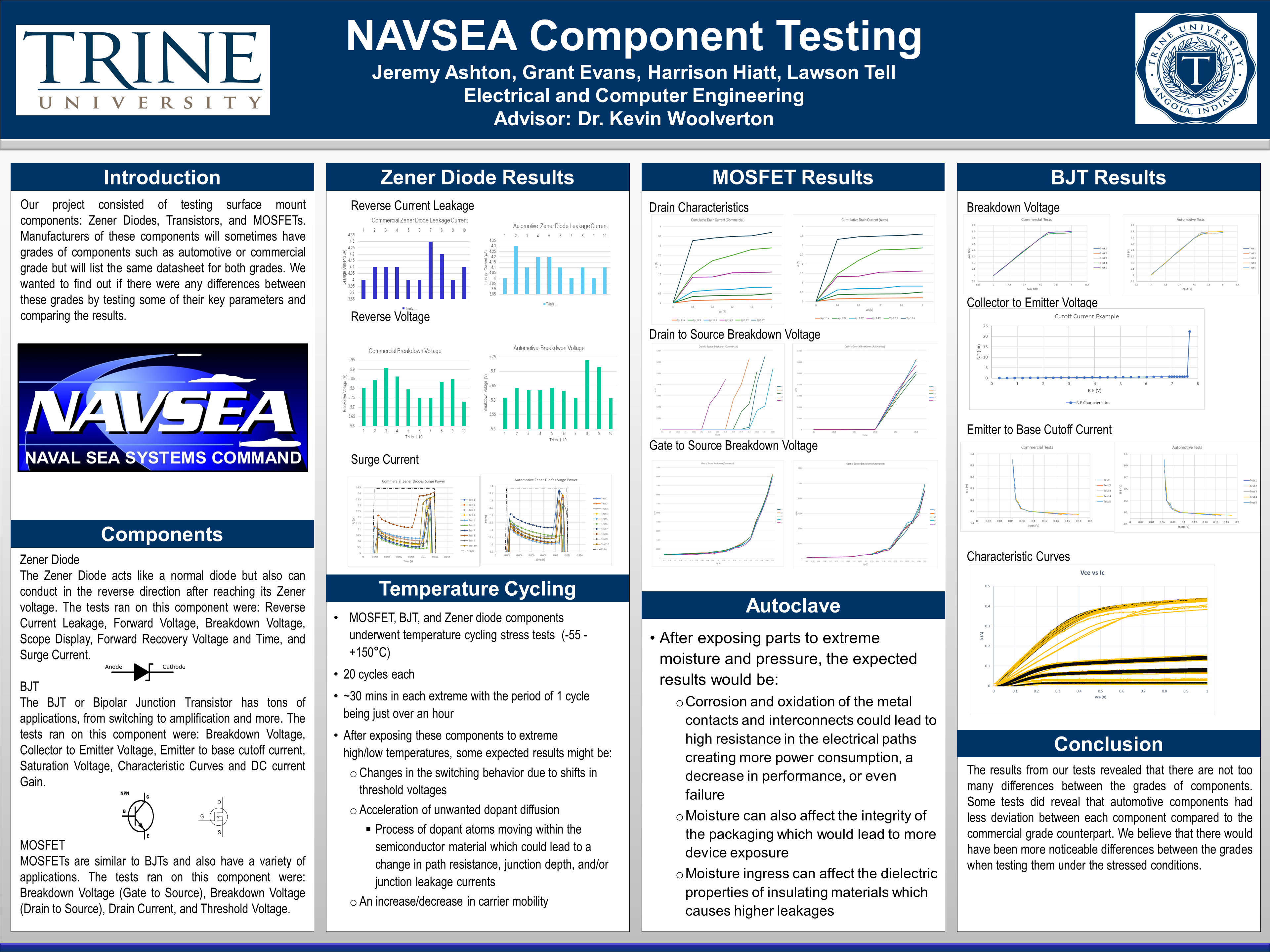

Our project consisted of testing surface mount components: Zener Diodes, Transistors, and MOSFETs. Manufacturers of these components will sometimes have grades of components such as automotive or commercial grade but will list the same datasheet for both grades. We wanted to find out if there were any differences between these grades by testing some of their key parameters and comparing the results.

Members: Jeremy Ashton, Grant Evans, Harrison Hiatt and Lawson Tell

According to the U.S. General Services Administration Office of Motor Vehicle Management,

there are 6.42 million car crashes in

the United States per year, and 98%, or 6.29 million of them are because of human

error. With

this statistic, the need to implement autonomous

driving becomes apparent. With many companies

making autonomous vehicles, the idea of being a

part of the making of autonomous vehicles seemed rational to be a part of the growing

industry. In the growing world of aircraft and

automation, there is a greater demand for the

ability of autonomous flight in an aircraft combined with the ability to take manual

control

of the aircraft. The problem is designing, building,

and programming a drone that has the ability to fly under the operation of a controller

or lock on to a predefined color, and then autonomously track. The biggest part of

any vehicle design is safety which is why it is imperative that the drone be programmed

to autonomously land safely in the case of any failure or other critical scenario

like a low battery.

Members: Nikolas Pensyl, Luke Fackler, Jarrett Johns and Khoa Weston

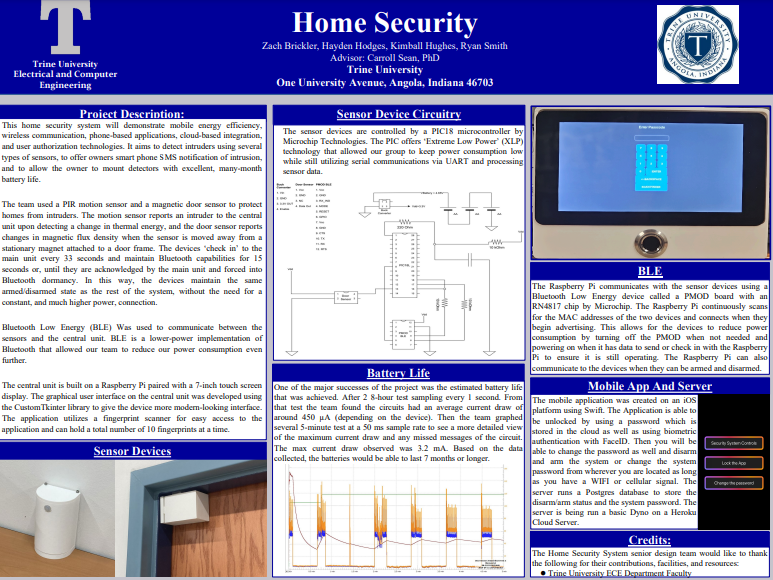

This home security system will demonstrate mobile energy efficiency, wireless communication,

phone-based applications, cloud-based integration, and user authorization technologies.

It aims to detect intruders using several types of sensors, to offer owners smart

phone SMS notification of intrusion, and to allow the owner to mount detectors with

excellent, many-month

battery life.

Members: Zach Brickler, Hayden Hodges, Kimball Hughes and Ryan Smith

Wade Department of Mechanical and Aerospace Engineering

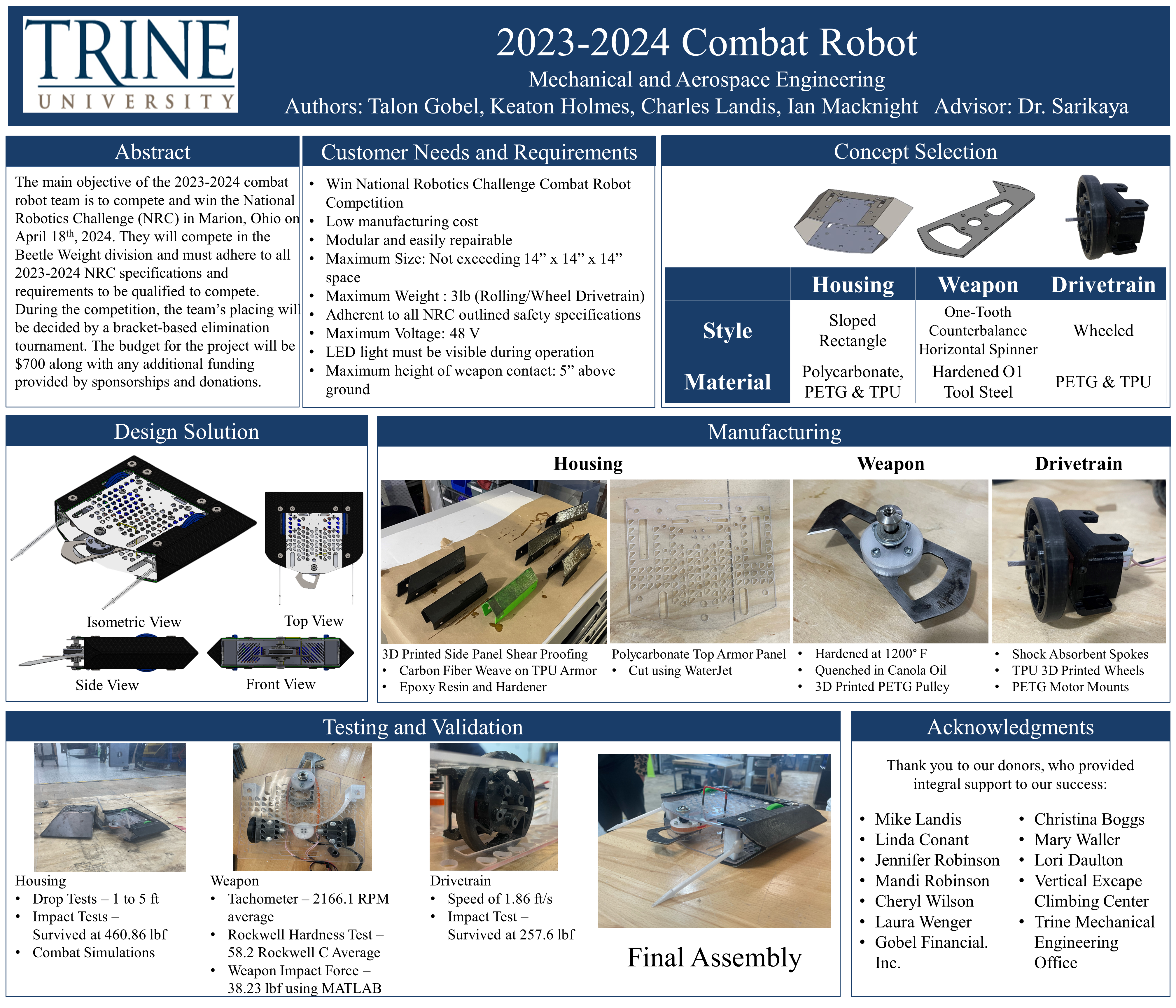

The main objective of the 2023-2024 combat robot team is to compete and win the National Robotics Challenge (NRC) in Marion, Ohio on April 18th, 2024. They will compete in the Beetle Weight division and must adhere to all 2023-2024 NRC specifications and requirements to be qualified to compete. During the competition, the team’s placing will be decided by a bracket-based elimination tournament. The budget for the project will be $700 along with any additional funding provided by sponsorships and donations.

Members: Talon Gobel, Keatson Holmes, Charles Landis and Ian Macknight

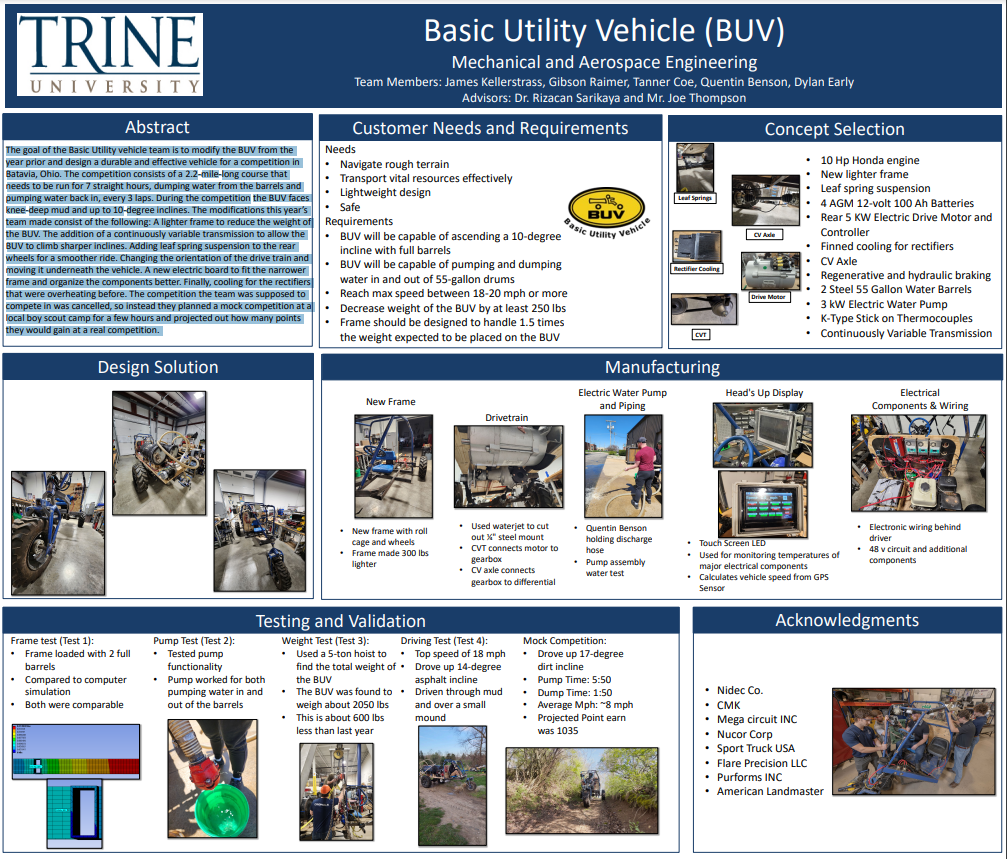

The goal of the Basic Utility vehicle team is to modify the BUV from the year prior

and design a durable and effective vehicle for a competition in

Batavia, Ohio. The competition consists of a 2.2-mile-long course that needs to be

run for 7 straight hours, dumping water from the barrels and pumping water back in,

every 3 laps. During the competition the BUV faces knee-deep mud and up to 10-degree

inclines. The modifications this year’s team made consist of the following: A lighter

frame to reduce the weight of the BUV. The addition of a continuously variable transmission

to allow the BUV to climb sharper inclines. Adding leaf spring suspension to the rear

wheels for a smoother ride. Changing the orientation of the drive train and moving

it underneath the vehicle. A new electric board to fit the narrower frame and organize

the components better. Finally, cooling for the rectifiers that were overheating before.

The competition the team was supposed to compete in was canceled, so instead they

planned a mock competition at a local boy scout camp for a few hours and projected

out how many points they would gain at a real competition.

Members: James Kellerstrass, Gibson Raimer, Tanner Coe, Quentin Benson and Dylan Early

The Mechanical Engineering Department representing Trine University for the Artificial Intelligence Maritime Maneuver (AIMM) Indiana Collegiate Challenge (ICC) designed and developed a device to collect rings off buoys along a course and retrieve an object from the water safely. The team brainstormed and developed concepts for different subsystems for the device. Once the best system was chosen for the device, the team went through multiple iterations from gathering information from finite elemental analysis, real life material testing, prototyping, and computational fluid dynamics. Based on the testing and calculations the device chosen to complete the tasks mentioned earlier was a crane. Once the final iteration was designed, the team manufactured the crane and mounted it to the low-profile vehicle (LPV). Once the team had the crane securely mounted, the team worked with the Electrical and A.I. departments to clarify whether the crane was communicating with the rest of the systems on the boat. Once the mechanical team goes through multiple tests with the full team, including dynamic testing whilst mounted to the boat, the team will go to Pokagon State Park in Angola Indiana for the AIMM ICC.

Members: Nathaniel Acres, Garrett Adams, Shelby Altman, Mason Bledsoe, Mason Custer, Mitchell Dickman, Roger Ellyson, Cole Goodman, Coltin Haylett, Brogan Jones, Kyle Kirtley, Asher Markitan, Alexander Menelli, Daniel Siebeneck and Trenton Vanderkuyl

The Cast in Steel competition strives to encourage students to learn about making steel products using the casting process and applying the latest technology available. This challenge is presented by the Steel Founders’ Society of America (SFSA). Simulations of the liquid metal flow and finite element analysis on the Halligan bar were conducted to ensure the design was valid. The students cast the final Halligan bar design with a medium-carbon steel recipe at the Trine University Foundry. Then, the Halligan bar was cleaned, heat treated, polished, and coated. The final Halligan bar is 29.75 in. long with a 1 in. diameter handle and weighs 12.9 lbs. (5.85 kg.). With the final product, testing was conducted to ensure the strength and durability of the material would be able to withstand the final performance evaluation at the competition. The team traveled to the 2024 Cast in Steel competition in Milwaukee, WI to compete against other schools in a series of tests to prove the functionality and durability of their Halligan bar.

Members: Grant Whitham, Reed Ellis, Dane Robertson, Brennen McNeil, Hayden Smith, Jonathan Stockwell and Josiah Guerra